High-precision Multifunctional Valve Double-sided CNC Boring And Milling Machine

|

|

Double-sided CNC boring and milling machine

Double-sided CNC boring machine is a CNC machine tool specially used for double-sided boring processing. Boring is a precision processing technology for processing holes and inner diameters, usually used to process high-precision holes or inner diameter surfaces. Double-sided CNC boring machine is controlled by a CNC system and can complete double-sided boring tasks efficiently and accurately. It is suitable for production environments that require high precision and high efficiency.

Main features 1. High-efficiency double-sided synchronous processing: Double-sided CNC boring and milling machines can process from both sides of the workpiece at the same time, which is particularly suitable for symmetrical workpieces, such as booms and dipper arms of engineering machinery. This design reduces the secondary clamping time required for traditional single-sided processing, shortens the processing time by more than 50%, and significantly improves production efficiency. 2. High-precision guarantee: Through synchronous control of the CNC system, the geometric tolerances (such as parallelism and coaxiality) of symmetrical features are ensured to avoid deviations caused by multiple processing. The double-sided cutting force is evenly distributed, reducing the deformation of the workpiece caused by heating caused by single-sided processing, which is particularly suitable for long-span workpieces. 3. Multi-functional composite processing: With functions such as multi-axis linkage and automatic tool change, boring cutters, milling cutters, taps and other tools can be quickly switched to meet the needs of multi-hole systems and multi-slots. This flexibility makes the double-sided CNC boring and milling machine more efficient when processing complex workpieces. 4. Save labor and reduce costs: Only one set of fixtures is needed for symmetrical workpieces, which reduces fixture costs. Automated processing reduces human errors, improves consistency, and saves labor costs. 5. Structural features: Double-sided CNC boring and milling machines usually use servo motors to drive the movement of each coordinate, which is easy to operate and has stable accuracy. Its basic structural layout is that the slide moves through the entire length of the bed, with a single-sided open type, a simple and convenient structure, and is convenient for the upper and lower installation and cleaning of the workpiece. In addition, the double-sided boring and milling machine is also equipped with a special mobile workbench and a double-sided boring and milling axis, which can perform drilling, milling, boring and other processing on the workpiece within the effective travel range, with fast loading and unloading speed and fast positioning speed.

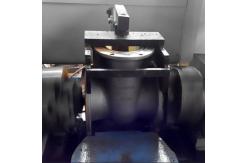

Application 1. Casting valves: various valves, such as gate valves, butterfly valves, check valves, etc. 2. Casting water pumps: water pumps of various diameters and shapes. 3. Fire protection industry: fire hydrants and other water supply and drainage facilities. 4. Pipe fittings industry: various flange pipe fittings.

Details

Processed product

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Double-sided boring milling machine High-precision boring milling machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customized Three-sided CNC Boring And Milling Machine For Processing Filters |

|

Customized CNC Boring And Milling Machine For Processing Silencer Check Valves |

|

Customized Three Sided CNC Boring And Milling Machine For Fire Hydrant Processing |

|

Customized multifunctional valve single-sided CNC boring and milling machine |

|

Customized Multifunctional Valve Double-sided CNC Boring And Milling Machine |

|

Customized High-precision Single-sided CNC Valve Boring And Milling Machine |