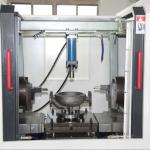

Six station Rotary Table Butterfly Valve Processing Machine

|

|

Six-station Rotary Table Butterfly Valve Processing Machine Application

The machine tool is applied to the processing of the valve stem hole, flange surface drilling, and the outer circle of the flange of the butterfly valve. It has high processing efficiency, high processing accuracy, stable processing dimensions, and is convenient for machine operation.

Advantages

It can simultaneously complete the machining of five processes: turning the outer circle of the small flange face of the butterfly valve, drilling, reaming, boring, and drilling the flange end face of the middle valve stem hole.

Characteristic

High processing accuracy:The centerline valve rod hole coaxiality is less than 0.05, symmetry less than 0.10, processing dimensions are stable

High uniformity in processing dimensions: This machine tool employs a numerical control system, eliminating the need for repeated tool setting, thereby enhancing dimensional stability and uniformity.

Simple to operate, the machine tool adopts servo control, and those with experience in CNC operation will learn in no time.

Details

Process Product

|

|||||||||||||||||||||||||||||||||||

| Product Tags: Butterfly Valve Processing Machine Rotary Table Processing Machine Six station Butterfly Valve Processing Machine |

|

Customized Three-sided CNC Boring And Milling Machine For Processing Filters |

|

Customized CNC Boring And Milling Machine For Processing Silencer Check Valves |

|

Customized Three Sided CNC Boring And Milling Machine For Fire Hydrant Processing |

|

Double Sided Cast Iron Valve Cnc Turning And Milling Lathe Machine |

|

Servo Motor 7.7-15 N.m CNC Lathes For API 6D ASME B16.34 Compliance Oil Gas Valve Machining Surface Roughness 6.3 |

|

Double Sided Cnc Turning And Milling Boring Lathe Machine For Sluice Valve |