Energy Saving Plastic Pipe Machine Stable PVC Extrusion Low

Noise Operation

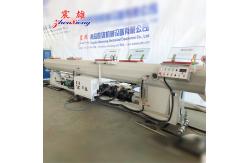

The PVC pipe production line developed and manufactured by

Zhenxiong Machinery adopts a PLC intelligent control system to

achieve automatic control of the entire production line, stable

operation, convenient production operation and maintenance of the

production line, reduce employee labor intensity, and improve

production efficiency.

Core advantages: - The PVC pipe production line adopts a large long diameter conical

twin-screw extruder with a reasonable screw design to ensure high

production while good material shearing and plasticizing quality

and low energy consumption.

- The PVC pipe production line adopts a professionally designed PVC

pipe extrusion die to ensure that the material can flow smoothly

and evenly, the pipe can be quickly formed, and the yield rate is

improved.

- The PVC pipe production line can greatly reduce the noise of the

vacuum box and achieve energy saving by automatically adjusting the

speed of the vacuum pump.

- The traction device of the PVC pipe production line adopts variable

frequency speed regulation to ensure a stable speed regulation

range, stable speed and reduce waste.

- The PVC pipe production line can be equipped with automatic

supporting equipment such as online expanding machine to meet the

expansion of different pipe diameters and help high-efficiency

production.

- The sizing of PVC pipes, with a sizing sleeve with a pre-cooling

device at the inlet end, is suitable for high-speed extrusion of

pipes.

- The PVC pipe production line is equipped with a fully automatic

chip-free cutting machine, which has stable cutting and no cleaning

troubles.

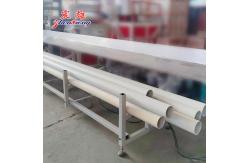

- The pipes produced by the PVC pipe production line have advantages

such as smooth pipe wall, light weight, high tensile and

compressive strength, and high corrosion resistance.

Item | SJGF-50 | SJGF-110 | SJGF-160 | SJGF-250 | SJGF-400 | SJGF-630 | Extruder | SJZ45 | SJZ55 | SJZ65 | SJZ65 | SJZ80 | SJZ92 | Pipe range | 16-40 | 50-110 | 63-160 | 110-250 | 200-400 | 315-630 | Vacuum tank(mm) | 5000 | 5000 | 5000 | 6000 | 6000 | 6000 | Cutting machine (m/min) | 3-12 | 2-8 | 2-8 | 0.4-3 | 0.2-4 | 0.4-3 | Total power (kw ) | 66 | 62 | 89 | 95 | 135 | 255 | Total length(mm) | 17000 | 18000 | 20000 | 20500 | 28000 | 30000 |

PVC Classification of pipe specifications:

Pipe specification | Extruduer | Output kg/h | Remark | 20-63 | 51/105 | 80-120 | 20,25,32,40,50,63 | 75-160 | 65/132 | 150-250 | 75,90,110,125,140,160 | 160-315 | 80/156 | 250-350 | 160,180,200,225,250,280,315 | 315-630 | 92/188 | 600-750 | 315,355,400,450,500,560,630 |

PVC pipe application range: PVC pipes are divided into two types: PVC water supply pipes and

drainage pipes, which are used for municipal water supply and

drainage, industrial water supply and drainage, civil water supply

and drainage, irrigation, vegetation watering, etc.

|