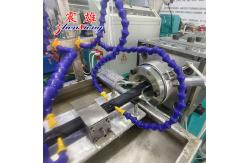

Semi Automatic Door Gasket Production Line Cost Effective Flexible

Production

Our company is a professional manufacturer of refrigerator door

gasket production lines, with over 20 years of production and

research and development experience.

The semi-automatic refrigerator door gasket production line

consists of an extruder, a head mold, a cooling water tank, and a

traction cutting machine. It has high mechanical efficiency and

flexible manual operation, and can be adjusted flexibly according

to different production needs to improve production efficiency.

Core advantages:

●The semi-automatic refrigerator door gasket production line adopts

SJ75 extruder, equipped with PVC professional separation screw,

with high production capacity and good material plasticization

effect.

●The head mold of the semi-automatic refrigerator door gasket

production line is made of 40Cr mold steel material, quenched,

tempered and forged, with high strength, wear resistance, and mold

accuracy.

●The semi-automatic refrigerator door gasket production line is

equipped with a 5P air-cooled chiller unit, which allows the

products to cool and solidify quickly. The cooling water

temperature can be manually adjusted and controlled as needed.

●The semi-automatic refrigerator door gasket production line is

equipped with an automatic drying and feeding machine, which

automatically alarms for overload and shortage, reducing labor

costs;

●The semi-automatic refrigerator door gasket production line has

two cooling water tanks, each section is 4 meters long, and the

cooling water path is long. It adopts circulating water spray

cooling, which is fast and uniform, and the product shaping effect

is good.

●The semi-automatic refrigerator door gasket production line

automatic cutting device can achieve high-precision fixed length

cutting.

Product application scope:

The door seal products produced by the semi-automatic refrigerator

door gasket production line have a smooth surface without burrs,

strong elasticity, uniform thickness, wear resistance, high and low

temperature resistance, high and low temperature resistance, and

are not easily aged or deformed after long-term use. Widely used in

various refrigerators, freezers, water dispensers, beverage

cabinets, disinfection cabinets, kitchenware, profile doors and

windows, as well as various daily products and other industrial

products.

Weight | 1.5 T | Capacity | 8 - 15/minute |

Power Consumt | 22 KW | Operating Mode | Semi - Automatic |

Voltage | 220V 380V / Customized | Dimensions | 1500x1600x1800mm |