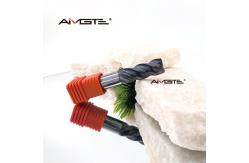

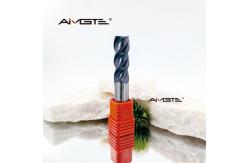

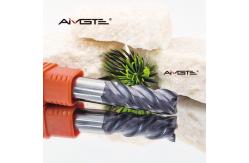

4 Flute Variable Helix Carbide End Mill Mold Steel Machining with TiAlN Coating

|

|

4 Flute Variable Helix Carbide End Mill Mold Steel Machining with TiAlN Coating Introduction: Our 4-flute variable helix carbide end mill is engineered specifically for high-performance mold steel machining, delivering exceptional efficiency and precision in demanding applications. Featuring an advanced TiAlN coating and variable helix geometry, this end mill reduces vibration, extends tool life, and maximizes material removal rates (MRR) in hardened steels like H13, P20, S136, and D2 (up to 55 HRC). Ideal for roughing, semi-finishing, and finishing, it ensures superior stability and surface quality in mold & die manufacturing.Features: ✔ 4-Flute Variable Helix Design – Breaks up harmonic vibrations for smoother cuts and reduced chatter

Advantages:✅ 30% Higher MRR – Aggressive cutting parameters with stability

Applications:

Detailed Pictures: Our workshop: New Customer Special Offers: To help you experience our premium products, we’re excited to offer the following exclusive promotions for first-time buyers: 1.Free Test Samples Get free samples (total value ≤ $20 USD) when you cover the international shipping cost. Perfect for evaluating our product quality and performance risk-free. 2.$50 USD Discount on First Order New customers can enjoy a $50 discount on the first order of $500 or more. A great way to start our partnership with extra value! Our advantages: 1.Advanced grinding machines: All of our grinding machines are WALTER and SAACKE brands. 2.Advanced inspection machines: We have ZOLLER, OMEGA, PG1000, etc. For inspecting each carbide tools. 3.Fast feedback: we offer 24 hours online service

Related products: |

| Product Tags: TiAlN Coating Carbide End Mill Mold Steel Machining Carbide Endmill |

|

Premium 20mm 4 Flute Carbide Ball Nose End Mill Extra Long Life for Steel Titanium Hard Metals |

|

150mm Full Length 4 Flute Carbide End Mill for Soft Metals Die Cast Aluminum Copper Brass |

|

10mm 2 Flute Solid Carbide Ball Nose Endmill HRC60 Hardened Steel Milling Cutter TiAlN Coated CNC Contouring Tool Precision Radius Cutting |

|

3mm 4 Flute Solid Carbide End Mill Micro Grain Tungsten Steel Milling Cutter for Steel CNC Precision Tool HRC55 Hardness TiAlN Coated |

|

12R3 4 Flute Carbide Corner Rounding End Mill For Stainless Steel High Temp Alloys CNC Milling Cutter |

|

4 Flute Solid Carbide 5mm square cutting end mill Flat Bottom CNC Cutting Tool for Steel Hard Metals |