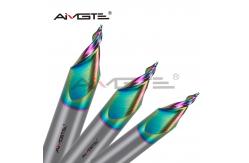

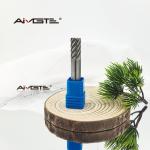

60 Degree Engraving Endmill 2 Flutes CNC End Mill Customized With DLC Coating

|

|

60 Degree Engraving Endmill 2 Flutes CNC Tool With DLC Coating For Aluminiun And Brass

Introduction:

A 60-degree engraving endmill with 2 flutes and DLC coating is an excellent choice for precision engraving, chamfering, and detail work in aluminum and brass.

Features:

60° Tapered Tip Design:

2-Flute Design:

DLC Coating (Diamond-Like Carbon):

Solid Carbide Construction:

Recommended Applications:

✔ Engraving serial numbers, logos, or fine details

Why DLC Coating for Aluminum/Brass?

DLC (Diamond-Like Carbon) coating is one of the best choices for machining aluminum, brass, and other non-ferrous metals due to its unique properties:

1. Prevents Built-Up Edge (BUE) & Material Adhesion

2. Reduces Friction & Heat Generation

3. Chemical Inertness (Non-Reactive with Aluminum/Brass)

4. Exceptional Wear Resistance (Even Without High Hardness)

5. Mirror-Like Surface Finish

Detailed Pictures: Our workshop:

Promotion policy:

To help you experience our premium products, we’re excited to offer the following exclusive promotions for first-time buyers:

1.Free Test Samples Get free samples (total value ≤ $20 USD) when you cover the international shipping cost. Perfect for evaluating our product quality and performance risk-free.

2.$50 USD Discount on First Order New customers can enjoy a $50 discount on the first order of $500 or more. A great way to start our partnership with extra value!

Other products:

FAQ: 1. Are you a manufacturer or trading company? We are a professional manufacturer of carbide tools which established in 2017.

2. Which CNC grinding machine do you use? All of our carbide tools are produced by imported WALTER grinding machines.

3. Which shipping method do you usually use? We usually send goods by express like FedEx, UPS, DHL, TNT, EMS, ETC. We also can send products to your shipping agent in China. |

| Product Tags: CNC Engraving End Mill 2 Flutes CNC End Mill DLC Coating CNC End Mill |

|

8.6mm 3 Flute Carbide Shank Relief End Mill AlTiCrN Coated for Mold Steel Die Casting High Feed Flat Bottom CNC Milling Cutter |

|

4 Flute Carbide Stepped Ball End Mill Precision Forming Cutter for 3D Profiling CNC Milling Tool Multi Level Radius Cutting 2mm-12mm Diameter |

|

Tungsten Carbide 3 Flute T Slot End Mill Deep Hole Milling Cutter for Die Steel Extra Long Reach CNC Router Bit 1/4" 3/8" 1/2" Shank |

|

16mm 8 Flute Carbide Finishing End Mill High Precision CNC Milling Cutter for Steel Aluminum 45° Helix Angle Mirror Finish |

|

Custom Solid Tungsten Carbide T Slot Cutter 4 Flute T Type Milling Tool for CNC Metalworking Machinery Grooving OEM ODM Available |

|

7.5mm 4 Flute DLC Coated Stepped End Mill Solid Carbide Multi Level Milling Cutter Precision Forming Tool for Steel Titanium CNC Machining |