|

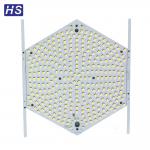

3535 5w 20w led pcb board 30 watt led bulb bare mcpcb aluminum 2835 led pcba Products Description: | PCB layers: | 1-24layers | | PCB materials: | CEM1, CEM3, Teflon, Rogers, FR-4, High Tg FR-4, Aluminum Base, Halogen Free | | PCB max. board size: | 620*1100mm (Custom) | | PCB certificate: | RoHS Directive-Compliant | | PCB Thickness: | 1.6 ±0.1mm | | Out Layer Copper Thickness: | 0.5-5oz | | Inner Layer Copper Thickness: | 0.5-4oz | | PCB max. board thickness: | 6.0mm | | Minimum Hole Size: | 0.20mm | | Minimum Line Width/Space: | 3/3mil | | Min. S/M Pitch: | 0.1mm(4mil) | | Plate Thickness and Aperture Ratio : | 30:1 | | Minimum Hole Copper: | 20µm | | Hole Dia. Tolerance(PTH): | ±0.075mm(3mil) | | Hole dia. Tolerance(NPTH): | ±0.05mm (2mil) | | Hole Position Deviation: | ±0.05mm (2mil) | | Outline Tolerance: | ±0.05mm (2mil) | | PCB solder mask: | Black, white, yellow | | PCB surface finished: | HASL Leadfree,Immersion ENIG,Chem Tin,Flash Gold,OSP,Gold finger,Peelable,Immersion Silver | | Legend: | White | | E-test: | 100% AOI, X-ray, Flying probe test. | | Outline: | Rout and Score/V-cut | | Inspection Standard: | IPC-A-610CCLASSII | | Certificates: | UL (E503048),ISO9001/ISO14001/IATF16949 | | Outgoing Reports: | Final Inspection, E-test, Solderability Test, Micro Section and More | | PCBA Technical Capability | | | 1. Assembly Type:: | FR4, FPC, Rigid-flex PCB, Metal base PCB. | | 2. Assembly Specification: | Min size L50*W50mm; Max size: L510*460mm | | 3. Assembly thickness: | Min thickness: 0.2mm; Max thickness: 3.0mm | | 4. Components Specification | | | Components DIP: | 01005Chip/0.35 Pitch BGA | | Minimum device accurace: | +/-0.04mm | | Minimum footprint distance: | 0.3mm | | 5. File format: | BOM list; PCB Gerber file: | | 6. Test | | | IQC: | Incoming inspection | | IPQC: | Production inspection; first ICR test | | Visual QC: | Regularly quality inspection | | SPI test : | Automatic solder paste optical inspection | | AOI: | SMD component welding detection, components shortage & component polarity detection | | X-Ravd: | BGA test; QFN and other precision devices hidden PAD device inspection | | Function test: | Test function and performance according to customer's test procedures and steps | | 7. Reworking: | BGA rework equipment | | 8. Delivery Time | | | Normal delivery time: | 24 hours( fastest 12 hours quick-turn) | | Small production: | 72 hours( fastest 24 hours quick-turn) | | Medium production: | 5 working davs. | | 9. Capacity: | SMT assembly 5 million point/day;plug-in & welding 300,000 point/day; 50-100 items/day | | 10. Components Service | | | A full set of substitute materials: | Have a experience component procurement sourcing, management system, and provide cost-effective services for OEM projects | | Only SMT: | Do SMT and backhand welding according to components PCB boards provided by customers. | | Components purchasing: | Customers provide core components, and we provide components sourcing services. | Why choose Hansion PCB Assembly? 1.More than 12 years experience of electronic manufacturing sevices for PCB making. 2.One stop service | PCB Manufacturing | Components sourcing and PCB assembly to help you easily achieve your electronic products. 3.more than 1000 customers working with us telecom, IOT, RF, smart control, security,medical,industrial,automotive, 3G / 4G / 5G products. 4.Reasonable and stable price: have established a strong global electronics components supply chain that help us get reasonable and stable pric 5.Quality assurance: more than 15 years experienced engineering team and quality control team to ensure all products come out under control. 6.Professional replace-solution: help customers source professional replace-solution to achieve faster, lower cost with high quality components purchasing agent service. |