Nonferrous Metal Plastic Eddy Current Magnetic Separator Machine Price

|

|

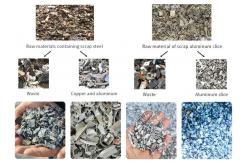

Products Description Eddy Current Separator Machine Xrido Machinery, a leading expert in resource recovery machinery,

proudly presents the NS series eddy current separator, designed to

efficiently separate non-ferrous metals such as aluminum, copper,

and zinc from various waste streams. With advanced technology and

precise engineering, our separator delivers exceptional performance

and contributes to sustainable development. Key Features and Benefits of the Eddy Current Separator • Powerful Eddy Currents: Equipped with high-performance magnets, our separator generates a powerful magnetic field of up to 3000 Gauss, ensuring efficient and precise metal separation. • Durable and Efficient Separation System: Our advanced separation system accurately identifies and separates non-ferrous metals like aluminum, copper, and zinc, handling a wide range of waste materials. • Automated Control: The fully automated control system minimizes operator error and ensures optimal performance, reducing downtime and operating costs. • Environmental Friendly: Our separator features a fully enclosed design to reduce dust emissions and maintain a clean working environment, contributing to a sustainable future. Product Paramenters

*This is the basic model of our Eddy Current Separator machine. Our

factory manufactures customized machines according to the different

requirements of different customers. Details Images

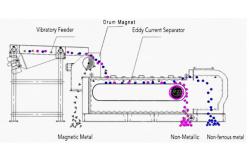

Working Principle Eddy Current Separation (ECS) is the use of the different

electrical conductivity property of material.the principle of

sorting isto use a magnet composed of permanent magnets simplified

and high-rotation Producing a magnetic field with

alternatingchanges in the county ,when the metal with electrical

conductivity pass the magnetic field , an eddy current itself will

Alternatethe magnetic field is changed ,and the direction of the

magnetic field generated By the rotation of the magneti is reserved

,insteadof no-iron metal (such as Aluminum ,copper )Will jump out

in the direction of its selection due to repelling ,and thus with

otherbroken glass,plastic Non-metallic substances materials are

separated to achieve the purpose of sorting. Applications • Electronic waste recycling: Separate valuable metals from electronic scrap. • Automotive recycling: Recover non-ferrous metals from end-of-life vehicles. • Metal shredding: Process shredded metal to extract valuable materials. Product packaging Our company's products are shipped to all over the world, making

great contributions to environmental protection and resource

recycling around the world. At the same time our customers can make

considerable profits. This is the vision of our company and the

common wish of every customer. Company Profile Our factory has a 20 years history of manufacturing customized

machines for different clients with different requirements. The

price of machine and quality are guaranteed. We have been working

in the field of environmental protection and recycling machinery

for more than ten years. Countless customers have visited our

factory and gained a deeper understanding of our machines. We

welcome every customer who is willing to learn more about our

factory to visit the factory. You can be accompanied by an engineer

to explain technical parameters and personally test the operating

status of the machine. We are committed to giving you the best service and experience. Our factory has obtained many certificates and invention patents.

We are always moving forward in the pursuit of technological

innovation. Science and technology are the primary productive

forces. Only by mastering core technologies can enterprises develop

better and better. We keep moving forward on this road. We put

continuous efforts to obtain more technological progress and

recognition. It's our honor to be trusted by our customers. It's also the vision

of our company. We are constantly pursuing the satisfaction and

recognition from our customers. We are looking forward for every

opportunity of cooperation. We also provide is installation

direction and perfect after-sale service. We take every opinions of

our customers priciously. That's the most important way to improve

our service and customers' experience. FAQ Q: Do you accept Custom-made? A: Yes, we can custom the Tire Shredder machine according to

clients requirements. Q: How can i get a suitable Tire Shredder machine? A: Tell us your requirements, such as raw material, out put size, capacity etc, our engineer can recommend the suitable configuration and provide quotation for you. Q: How long is your delivery time ? A: 1 set for normal machine needs about 5 working days, if 1 or more containers, needs about 20 working days. Q: How long is the warranty? A: 1 year since the date of shipment, if parts failure or damage(because of the quality problem, except wearing parts), our company will provide these parts for free. Q:What is your payment term? A: T/T 100% before shipment, L/C at sign, or Trade Assurance order recommended. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 1000kg/h magnetic separator machine 1100kg/day magnetic separator machine 1000kg/h eddy current magnetic separator |

|

Eddy Current Separator Eddy Current Sorting Machine Manufacture Aluminium Sorting Machinery Copper Eddy Current Separator |

|

Aluminium Copper Non Ferrous Separation 2500KG/H-4500KG/H Eddy Current Separator |

|

20T/H Eddy Current Separator Aluminium Eddy Current Non Ferrous Separator |

|

Magnetic Eddy Current Aluminum Separation Non Ferrous PCB Metal Sorting Machine |

|

Copper Plastic Glass Sorter Equipment Automatic Strong Magnetic Separator Eddy-current Separator Eddy Current Metal Sorter |

|

Aluminum Copper Recycling Eddy Current Separator Non Ferrous Metal Separator Magnetic Separator |