200kg/H-1000kg/H Non Ferrous Metal Separation Eddy Current Metal Separator

|

Detailed Product Description

|

Aluminium Copper Recycling Separation Machine Eddy Current Separator Scrap Metal Non Ferrous Sorting Recycling Machines Products Description Eddy current separator is a solid waste sorting equipment based on

the principle of electromagnetic induction, which is mainly used to

efficiently separate non-ferrous metals from mixed materials. Its

core working principle is to generate an alternating magnetic field

through a high-speed rotating permanent magnetic roller or drum.

When conductive metals (such as copper, aluminum, etc.) pass

through the magnetic field, eddy currents will be induced inside

the metal, and then an induced magnetic field in the opposite

direction of the original magnetic field will be generated.

According to Lenz's law, this magnetic field interaction will

produce a repulsive force (Lorentz force), thereby ejecting and

separating the conductive metal, and realizing the automatic

sorting of non-ferrous metals and non-metallic materials (such as

plastics, glass, etc.). The equipment has the characteristics of

high sorting efficiency, low energy consumption, and high degree of

automation. It is widely used in electronic waste treatment,

automobile dismantling, industrial waste recycling and other

fields. It is one of the key technical equipment for realizing

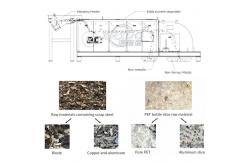

resource recycling and environmental protection treatment. Details Images The eddy current equipment is composed of two parts: control and

main body. The main part mainly consists of frame, motor,

distributor, separator (the core part of the equipment) permanent

magnetic drum, conveyor belt, conveyor drive drum, reducer and

protective cover.

Eddy current separator is suitable for a variety of solid waste

containing non-ferrous metals. The following are its main

applicable materials: 1. Electronic waste Circuit board fragments: Recycling conductive metals such as copper foil and aluminum components Scrap electrical appliances: Separating copper wire and aluminum shell from broken materials such as refrigerators and air conditioners Wires and cables: Separating copper core, aluminum core and insulating materials 2. Industrial waste Automobile dismantling materials: Recycling broken bridge aluminum and copper parts (such as radiators and wiring harnesses) Construction waste: Separating aluminum window frames, copper pipes and other metals Industrial slag: Extracting non-ferrous metal residues such as copper and zinc 3. Domestic solid waste Waste plastic doors and windows: Separating aluminum frames and plastics Glass bottle aluminum caps: Recycling aluminum in bottle caps Urban domestic waste: Separating mixed metal packaging (such as aluminum cans) 4. Other special materials Metal tailings: Recovering copper, aluminum, etc. from ore processing tailings Metal mixtures: Separating non-ferrous alloys such as copper, aluminum and zinc Customer Site Product packaging |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 1000kg/h non ferrous metal separation 200kg/h eddy current metal separator 200kg/h non ferrous metal separation |

Related Products

|

Eddy Current Separator Eddy Current Sorting Machine Manufacture Aluminium Sorting Machinery Copper Eddy Current Separator |

|

Aluminium Copper Non Ferrous Separation 2500KG/H-4500KG/H Eddy Current Separator |

|

20T/H Eddy Current Separator Aluminium Eddy Current Non Ferrous Separator |

|

Magnetic Eddy Current Aluminum Separation Non Ferrous PCB Metal Sorting Machine |

|

Copper Plastic Glass Sorter Equipment Automatic Strong Magnetic Separator Eddy-current Separator Eddy Current Metal Sorter |

|

Aluminum Copper Recycling Eddy Current Separator Non Ferrous Metal Separator Magnetic Separator |

Email to this supplier