CE Fabric Shredders Multifunctional Waste Cloth Shredding Machine

|

Detailed Product Description

|

Waste Clothes Textile Crusher Waste Fabric Shredder Machine for Leather Products Description Leather shredder is a device specially designed to handle leather

scraps or waste leather. It uses advanced technology and unique

design to efficiently shred leather into smaller pieces. The

working principle of a leather shredder is usually based on

powerful mechanical force, which quickly cuts and shreds leather

through high-speed rotating blades and powerful squeezing. This

equipment is widely used in the leather processing industry,

furniture manufacturing industry, and environmental protection

field, and helps to realize the resource utilization of leather

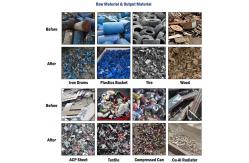

waste. The Double Shaft Shredder can meet the waste recycling requirements

of various industries, and is suitable for shredding thick and

difficult materials, such as: electronic waste, plastic,tire,

metal, wood, waste rubber, packaging barrels, pallets, etc. Technical Parameters

Advantages of waste fabric shredders 1. Efficient processing: The waste fabric shredder uses advanced shredding technology and high-speed rotating blades to quickly and evenly shred waste fabrics into small pieces, improving processing efficiency. 2,Wide material applicability: This equipment can smoothly shred various waste cloth ends, cotton spinning waste yarn, waste clothing, etc., and has a wide range of material applicability. 3, Intelligence and automation: Some waste cloth shredders are equipped with intelligent control systems and sensors, which can realize automatic operation and monitoring, and improve the overall efficiency and safety of the production line. The process of crushing waste textiles, cloths and leathers into

energy RDF (Refuse Derived Fuel): 1. Garbage pretreatment: Classify and screen waste textiles, cloths, leathers and other wastes to remove impurities and non-organic parts. Put the garbage into the feed belt conveyor through a grab car or manually, and transport it to the double-axis shear crusher for primary crushing (shearing, crushing, tearing). 2. Crushing and drying: The materials after primary crushing are iron-removed by a self-unloading iron remover, and then transported to the fine crusher for secondary crushing to reduce the particle size of the material and improve the efficiency of subsequent processing. For materials with high water content, the production line will add drying or bio-drying links to reduce the water content of the garbage and improve the calorific value and combustion performance of RDF. 3. Mixing and molding: Mix the crushed and dried garbage with appropriate additives (such as adhesives) to improve the moldability and stability of RDF. The mixed waste materials are pressed into RDF particles or fuel rods of a specific shape through molding equipment. 4. Quality inspection: The quality of the manufactured RDF is inspected, including the determination of indicators such as calorific value, moisture content, ash content, etc., to ensure that it meets the relevant standards and usage requirements. Finished product display: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ce fabric shredders fabric shredders multifunctional multifunctional waste cloth shredding machine |

Related Products

|

Textile Waste Shredding Disposal Solid Waste Shredder Waste Cloth Leather To RDF Briquette System Industrial Textile Waste Crusher |

|

Waste Textile Shredder Machine Two Shaft Cloth Leather Fabric Shredder |

|

Double Shaft Waste Old Clothes Recycling Fabric Foam Textile Shredder Machine |

|

Double Shaft Cloth Shredder Machine 200-10000kg/H Waste Cloth Shredding Machine |

|

Used Clothes Textile Waste Shredder Machine For Leather Non Woven Fabric |

|

Industrial Waste Fabric Textile Double Shaft Textile Cloth Shredder Machine for Textile |

Email to this supplier