440V 415V Garment Shredder Waste Fabric Shredder Machine Customized

|

Detailed Product Description

|

Plastic Recycling Textile Jeans Cloth Waste Fabric Shredder Machine Products Description Textile shredder is a mechanical equipment specially used to

process waste textiles (such as clothing, bed sheets, plush toys,

etc.). It uses mechanical forces such as shearing and tearing to

break large-volume textiles into small particles or fibrous

materials, which is convenient for subsequent sorting or

preparation of RDF fuel. The core equipment includes a

double-shaft/single-shaft shredder, which can solve the problem of

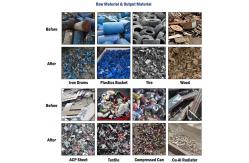

cloth winding and realize continuous processing. The Double Shaft Shredder can meet the waste recycling requirements

of various industries, and is suitable for shredding thick and

difficult materials, such as: electronic waste, plastic,tire,

metal, wood, waste rubber, packaging barrels, pallets, etc. Technical Parameters

Advantages of leather shredders Textile shredders have a wide range of applications, mainly covering the following aspects: Garbage disposal: Textiles are one of the common garbage components in the garbage disposal process. Textile shredders can be used to shred textile waste into small pieces, which is convenient for subsequent landfill, incineration or composting, reducing the volume of garbage and improving processing efficiency. Resource recycling: Textile shredders can convert discarded textiles into reusable resources, such as fibers, filling materials, etc. These materials can be used to make new textiles, furniture, building materials, etc., to achieve resource recycling and reduce dependence on primary resources. Energy field: In some cases, textile waste can also be used as a source of biomass energy. After the waste is shredded by a textile shredder, it can be used together with other biomass materials for power generation or heating to achieve sustainable use of energy. Product Application Successful Project The process flow of preparing RDF (waste-derived fuel) through

resource processing of waste textiles, cloth, leather, etc.: 1, Pretreatment and transportation Waste textiles enter the processing line through a chain

conveyor or a belt conveyor to achieve automatic loading. 2, Coarse crushing The material is coarsely crushed by a double-shaft shredder or an

industrial waste crusher to reduce the large volume of material to

a size suitable for subsequent processing. 3, Sorting and purification Magnetic separation : Separate ferromagnetic metal impurities and

recover metal resources. Wind separation : Use airflow to separate light combustibles (such as fabrics and plastics) from heavy impurities (such as sand and gravel). 4. Fine crushing The sorted combustibles enter the fine shredder and are further crushed into uniform particles of 50-100mm to meet the size requirements of RDF fuel. 5. Molding (optional) Some processes will add an RDF molding machine to compress the crushed materials into high-density particles or fuel rods for easy transportation and storage. 6. Finished product application The final RDF fuel can be directly used in cement kilns, power plants, etc. to replace coal and realize energy utilization. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: waste fabric shredder machine fabric shredder machine customized 440v textile shredder machine |

Related Products

|

Textile Waste Shredding Disposal Solid Waste Shredder Waste Cloth Leather To RDF Briquette System Industrial Textile Waste Crusher |

|

Waste Textile Shredder Machine Two Shaft Cloth Leather Fabric Shredder |

|

Double Shaft Waste Old Clothes Recycling Fabric Foam Textile Shredder Machine |

|

Double Shaft Cloth Shredder Machine 200-10000kg/H Waste Cloth Shredding Machine |

|

Used Clothes Textile Waste Shredder Machine For Leather Non Woven Fabric |

|

Industrial Waste Fabric Textile Double Shaft Textile Cloth Shredder Machine for Textile |

Email to this supplier