Waste Bucket Plastic Can Plastic Bottle Shredder Multifunctional

|

|

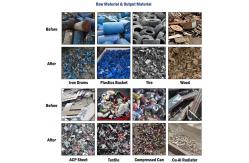

Products Description Plastic shredder is a mechanical equipment specially used for crushing, tearing and reducing the volume of waste plastic materials (such as plastic products, scraps, pipes, films, etc.). Its core function is to mechanically decompose large or complex plastic waste into smaller pieces or particles for subsequent recycling, regeneration or reduction. Main application scenarios of plastic shredders

Advantages of plastic shredder: 1. Wide range of materials to be processed: Plastic shredder is suitable for many types of plastics, including hard plastics (such as ABS, PC, PP boards, etc.), soft plastics (such as PE films, plastic bags, etc.) and composite plastic waste. It can handle large-sized, high-toughness plastic materials, such as plastic sheets, pipes, containers, etc. 2. Adjustable discharging particle size: Plastic shredders are usually equipped with replaceable screens. By adjusting the screen aperture, the discharging particle size can be controlled to meet different processing needs. The discharging particle size is generally between 20mm and 200mm, or even larger, which is suitable for occasions requiring larger particle sizes. 3. Low speed, high torque: The plastic shredder adopts a low speed, high torque design, which can more effectively handle hard plastics and reduce energy consumption and wear. The low speed design also reduces noise and dust pollution, meeting environmental protection standards. 4. Easy operation and maintenance: Plastic shredders usually have microcomputer automatic control

functions, which are easy to operate and easy to use. The equipment

has a compact structure, small footprint, and is easy to install

and layout. Low maintenance costs, economical and durable, and

wearing parts such as knives and screens are easy to replace. 5.

High safety: Plastic shredders use advanced safety protection

technologies, such as overload automatic reversal control

functions, emergency stop buttons, etc., to ensure safety during

operation. Product Application Successful Project Our Advantage 1. It has the characteristics of low speed, high torque and low

noise. It is controlled by PLC. It has the functions of

starting,stopping, reversing and overloading automatic reversing. 2. The motor + reducer drives the cutter shaft to achieve the shearing effect of low speed and high torque. 3. Bearing six-fold seal, effective waterproof and dust-proof, prolong the service life of bearings. 4. After tool wear, the repair technology of tool coating and welding is adopted to realize the repeated use of the tool, which greatly reduces the maintenance cost of the tool. 5. Separate box design, can easily and quickly remove the entire axle (axle, blade, bearing, sealing system). 6. Tools are arranged according to helix to achieve high efficiency cutting. 7. Both the inner hole and the spindle face of the cutter are designed in hexagonal form to realize the uniformity of the force exerted on the cutter. 8. According to different materials and product shapes to be torn up, different types of cutters can be selected. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: waste plastic shredder waste plastic lumps shredder machine pa plastic shredder | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

380V 220V Mini Aluminum Can Shredder Small Plastic Crusher Plastic Drum Shredder |

|

Waste Plastic Barrel Shredder 55kw Big Plastic Lumps Shredder Machine |

|

Plastic Blue Barrel Plastic Trash Can Crushing Machine Shredder for Recycling |

|

Multifunctional Plastic Bottle Shredder Machine Double Shaft 50kw |

|

Plastic Bumper Shredder Machine Plastic Waste Barrel Shredder |

|

Dual Shaft Plastic Film Shredder Waste Recycling Two Shaft Shredder |