High Efficiency Waste Shredder Machine Automatic Plastic Twin Shaft Shredder

|

Detailed Product Description

|

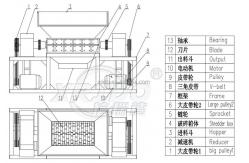

High Efficiency Waste Shredder Machine Automatic Double Shaft Plastic Metal Material Factory Direct Sales Products Description The double-axis waste shredder is an "all-around warrior" for solid

waste treatment. It uses two counter-rotating alloy blade shafts to

shred electronic waste, medical waste plastics and other materials

into uniform fragments. The work process is divided into three

steps: feeding → shearing and extrusion → discharging. The unique

four-corner blade design avoids material entanglement. The

advantage is that it can handle high-viscosity materials without

jamming the machine. For example, waste tire rubber blocks can be

torn into 50mm particles and directly used for rubber track paving,

which reduces carbon emissions by 80% compared with traditional

incineration treatment. Details Images Motor The shredder adopts a full copper core motor to reduce energy

consumption and have a longer service life. Shredder Chamber The materials enter the blades chamber through the feeding system,

they are shredded into small pieces. Using high quality carbon

steel making. It's strong and durable. Reducer The gearbox of the shredder is welded with steel plates, with high

accuracy, good contact, low noise and long service life. Double shaft Double shaft shredder adopts two-axis independent drive, so that

the production of materials to produce the corresponding pressure

to achieve automatic feedingfunction Main Application waste steel parts Steel barrel, waste bike, scrap cars, used car body, light metal,

motorbicycle, waste square steel, metal pipe etc. waste appliance parts waste refrigerator scrap, used TV sets, waste air conditioner,

micro woven, PCB board etc. wood part and paper waste part wood branch, furniture scrap, desk, chair, bed, mattress

etc.magazine scrap, book waste, industrial carton box, used

newspaper etc. *These are the most common raw materials in our daily life. If you

have specific requirements on raw materials, please kindly tell us.

Our engineer can give professional advice according to your

requirements and design plans for you. Product Paramenters

*This is the basic model of our shredder machine. Our factory

manufactures customized machines according to the different

requirements of different customers. Product packaging Customer Photos It's our honor to be trusted by our customers. It's also the vision

of our company. We are constantly pursuing the satisfaction and

recognition from our customers. We are looking forward for every

opportunity of cooperation. We also provide is installation

direction and perfect after-sale service. We take every opinions of

our customers priciously. That's the most important way to improve

our service and customers' experience. Company Profile Our factory has obtained many certificates and invention patents.

We are always moving forward in the pursuit of technological

innovation. Science and technology are the primary productive

forces. Only by mastering core technologies can enterprises develop

better and better. We keep moving forward on this road. We put

continuous efforts to obtain more technological progress and

recognition. Our factory has a 20 years history of manufacturing customized

machines for different clients with different requirements.

The price of machine and quality are guaranteed. We have been

working in the field of environmental protection and recycling

machinery for more than ten years. Countless customers have visited

our factory and gained a deeper understanding of our machines. We

welcome every customer who is willing to learn more about our

factory to visit the factory. You can be accompanied by an engineer

to explain technical parameters and personally test the operating

status of the machine. We are committed to giving you the best

service and experience. FAQ Q: Do you accept Custom-made? A: Yes, we can custom the Tire

Shredder machine according to clients requirements. Q: How can i get a suitable Tire Shredder machine? A: Tell us your requirements, such as raw material, out put size, capacity etc, our engineer can recommend the suitable configuration and provide quotation for you. Q: How long is your delivery time ? A: 1 set for normal machine needs about 5 working days, if 1 or more containers, needs about 20 working days. Q: How long is the warranty? A: 1 year since the date of shipment, if parts failure or damage(because of the quality problem, except wearing parts), our company will provide these parts for free. Q:What is your payment term? A: T/T 100% before shipment, L/C at sign, or Trade Assurance order recommended. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: waste shredder machine automatic plastic twin shaft shredder high efficiency waste shredder machine |

Related Products

|

Industrial Waste Crusher Solid Waste Crushing Machine Industrial Waste Processing Machine Metal Shredder |

|

Garbage Pre Crusher Machine Solid Waste Recycling Crushing Machine Metal Crushing Double Shaft Shredder |

|

Garbage Crusher Machine MSW Crusher Industrial Solid Waste Crusher Solid Waste Dispose Plant |

|

Glass Plate Crusher Waste Glass Shredder Waste Shredder Machine Solid Waste Shredder Industrial Waste Shredder Solid Waste Dispose Plant |

|

Glass Crusher Waste Glass Shredder Machine Solid Waste Shredder Industrial Waste Glass Crusher Solid Waste Dispose Plant |

|

Glass Bottle Shredder Automatic Waste Metal Shredder Plastic Shredder Industrial Shredding Machine Glass Crusher |

Email to this supplier