|

Faster Long High Speed Stroke Slide Table with ±0.1mm Precision Efficiency The PTB Synchronous Belt Slides are high-performance linear motion modules developed specifically for high-speed material handling and precision positioning in industrial automation. Centered on the core technical pillars of "high load capacity · ultra-high speed · strong thrust," they achieve threefold performance breakthroughs: a maximum horizontal load capacity of 200kg, an ultra-high operating speed of 2311mm/s, and a peak thrust of 1126N. This is enabled by the synergistic design of high-rigidity linear slides and 45mm-wide synchronous belts. With a flexible stroke range of 50-4000mm, they are widely applied in scenarios demanding speed and load capacity, such as logistics sorting, automotive component assembly, and electronic component placement, redefining the performance benchmark for mid-to-high-end linear motion modules. -

Logistics Sorting Centers

As the main conveying axis, PTB slides drive sorting carts at an ultra-high speed of 2311mm/s. With a maximum load capacity of 200kg, they effortlessly handle full boxes of goods. The 1126N peak thrust ensures rapid switching of sorting baffles, increasing hourly parcel processing from 2500 to 8000 units. -

Automotive Component Assembly

At engine block handling workstations, the dual-rail high-rigidity design, combined with a 200kg load capacity, stably transports engine blocks across machining and assembly stations. The ±0.1mm repeat positioning accuracy meets the alignment requirements for bolt holes. -

Electronic Component Placement

In FPC flexible board pressing equipment, the 1126N strong thrust and 45mm-wide belt’s high stability achieve 0.1mm-level pressing precision, resolving issues of loose or misaligned pressing caused by insufficient thrust in traditional slides. -

High-Rigidity Load Bearing: Effortless 200kg Horizontal Handling

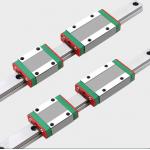

Featuring an integrated design of dual-row high-rigidity linear slides and a thickened aluminum alloy base plate, the contact surfaces of slides and rails undergo ultra-precision grinding. Paired with a 45mm-wide PM-type synchronous belt, this configuration delivers a 200kg dynamic load capacity in the horizontal direction. Even when handling heavy workpieces like automotive gearboxes or large battery modules, the slide maintains low deflection deformation of 0.1mm/m, ensuring motion stability. -

Ultra-High Speed: 3x Efficiency Improvement

Equipped with high-tension synchronous belts and a direct-drive low-inertia servo motor, the transmission efficiency reaches 97%. Combined with lightweight aluminum alloy sliders, the maximum linear speed surpasses 2311mm/s—30% faster than conventional synchronous belt slides. In logistics sorting scenarios, it enables high-speed sorting of 6000 parcels per hour, tripling efficiency compared to traditional chain conveyors. -

Full-Stroke Coverage: Flexible Adaptation to 50-4000mm

Using modular rail splicing technology, the stroke range spans 50-4000mm, enabling efficient adaptation from short-stroke precision dispensing to long-distance logistics conveying.

| PTB27 | | Specification | Repeatable positioning accuracy(mm) | ±0.08 | | Lead (mm) | 208 | | Reduction ratio | 3:1 | 5:1 | 7:1 | 10:1 | | Max speed(mm/s) | 2311 | 1386 | 990 | 693 | | Max load (kg) | Horizontal | 22 | 60 | 110 | 200 | | Vertical | ——— | | Rated thrust (N) | 367 | 613 | 858 | 1226 | | standard stroke (mm) | 50-4000mm/50 interval | | Component | AC servo motor capacity (W) | 1000 | | Belt width(mm) | 45 | | High rigidity linear slider | W28×H26 | | Sensor | PM-T45(NPN) |

| Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | | T | 786 | 836 | 886 | 936 | 986 | 1036 | 1086 | 1136 | 1186 | 1236 | 1286 | 1336 | 1386 | 1436 | 1486 | 1536 | 1586 | | B | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | | N | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | | KG | 39.8 | 41.6 | 43.4 | 45.2 | 47 | 48.8 | 50.6 | 52.4 | 54.2 | 56 | 57.8 | 59.6 | 61.4 | 63.2 | 65 | 66.8 | 68.6 | | Stroke | 1750 | 1800 | 1850 | 1900 | 1950 | 2000 | 2050 | 2100 | 2150 | 2200 | 2250 | 2300 | 2350 | 2400 | 2450 | 2500 | 2550 | |

| T | 2486 | 2536 | 2586 | 2636 | 2686 | 2736 | 2786 | 2836 | 2886 | 2936 | 2986 | 3036 | 3086 | 3136 | 3186 | 3236 | 3286 | | B | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | | N | 9 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 11 | 12 | 12 | 12 | 12 | 13 | 13 | 13 | 13 | | KG | 101 | 102.8 | 104.6 | 106.4 | 108.2 | 110 | 111.8 | 113.6 | 115.4 | 117.2 | 119 | 120.8 | 22.6 | 124.4 | 126.2 | 128 | 129.8 | | Stroke | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | 1400 | 1450 | 1500 | 1550 | 1600 | 1650 | 1700 | | T | 1636 | 1686 | 1736 | 1786 | 1836 | 1886 | 1936 | 1986 | 2036 | 2086 | 2136 | 2186 | 2236 | 2286 | 2336 | 2386 | 2436 | | B | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | | N | 5 | 5 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | | KG | 70.4 | 72.2 | 74 | 75.8 | 77.6 | 79.4 | 81.2 | 83 | 84.8 | 86.6 | 88.4 | 90.2 | 92 | 93.8 | 95.6 | 97.4 | 99.2 | | Stroke | 2600 | 2650 | 2700 | 2750 | 2800 | 2850 | 2900 | 2950 | 3000 | 3050 | 3100 | 3150 | 3200 | 3250 | 3300 | 3350 | 3400 | |

| T | 3336 | 3386 | 3436 | 3486 | 3536 | 3586 | 3636 | 3686 | 3736 | 3786 | 3836 | 3886 | 3936 | 3986 | 4036 | 4086 | 4136 | | B | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | | N | 14 | 14 | 14 | 14 | 15 | 15 | 15 | 15 | 16 | 16 | 16 | 16 | 17 | 17 | 17 | 17 | 18 | | KG | 131.6 | 133.4 | 135.2 | 137 | 138.8 | 140.6 | 142.4 | 144.2 | 146 | 147.8 | 149.6 | 151.4 | 1532 | 155 | 156.8 | 158.6 | 160.4 |

| Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | | T | 786 | 836 | 886 | 936 | 986 | 1036 | 1086 | 1136 | 1186 | 1236 | 1286 | 1336 | 1386 | 1436 | 1486 | 1536 | 1586 | | B | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | | N | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | | KG | 39.8 | 41.6 | 43.4 | 45.2 | 47 | 48.8 | 50.6 | 52.4 | 54.2 | 56 | 57.8 | 59.6 | 61.4 | 63.2 | 65 | 66.8 | 68.6 | | Stroke | 1750 | 1800 | 1850 | 1900 | 1950 | 2000 | 2050 | 2100 | 2150 | 2200 | 2250 | 2300 | 2350 | 2400 | 2450 | 2500 | 2550 | | T | 2486 | 2536 | 2586 | 2636 | 2686 | 2736 | 2786 | 2836 | 2886 | 2936 | 2986 | 3036 | 3086 | 3136 | 3186 | 3236 | 3286 | | B | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | | N | 9 | 10 | 10 | 10 | 10 | 11 | 11 | 11 | 11 | 12 | 12 | 12 | 12 | 13 | 13 | 13 | 13 | | KG | 101 | 102.8 | 104.6 | 106.4 | 108.2 | 110 | 111.8 | 113.6 | 115.4 | 117.2 | 119 | 120.8 | 122.6 | 124.4 | 126.2 | 128 | 129.8 | | Stroke | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | 1400 | 1450 | 1500 | 1550 | 1600 | 1650 | 1700 | | T | 1636 | 1686 | 1736 | 1786 | 1836 | 1886 | 1936 | 1986 | 2036 | 2086 | 2136 | 2186 | 2236 | 2286 | 2336 | 2386 | 2436 | | B | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | | N | 5 | 5 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | | KG | 70.4 | 72.2 | 74 | 75.8 | 77.6 | 79.4 | 81.2 | 83 | 84.8 | 86.6 | 88.4 | 90.2 | 92 | 93.8 | 95.6 | 97.4 | 99.2 | | Stroke | 2600 | 2650 | 2700 | 2750 | 2800 | 2850 | |2900 | 2950 | 3000 | 3050 | 3100 | 3150 | 3200 | 3250 | 3300 | 3350 | 3400 | | T | 3336 | 3386 | 3436 | 3486 | 3536 | 3586 | 3636 | 3686 | 3736 | 3786 | 3836 | 3886 | 3936 | 3986 | 4036 | 4086 | 4136 | | B | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | | N | 14 | 14 | 14 | 14 | 15 | 15 | 15 | 15 | 16 | 16 | 16 | 16 | 17 | 17 | 17 | 17 | 18 | | KG | 131.6 | 133.4 | 135.2 | 137 | 138.8 | 140.6 | 142.4 | 144.2 | 146 | 147.8 | 149.6 | 151.4 | 153.2 | 155 | 156.8 | 58.6 | 160.4 |

|