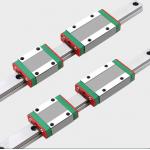

Recirculating Ball High Speed Linear Guide Rails Preload

Adjustable SEXGL Linear Guide Rails deliver unparalleled accuracy and durability in high-precision

automation systems, trusted by global leaders like BYD (EV

powertrain assembly) and BOE (LCD panel cutting robots) across

North America, Europe, Southeast Asia, and South Korea.Ball linear

guide rails are precision-engineered components designed to deliver

ultra-smooth, low-friction linear motion in demanding industrial

and automation settings. Featuring a recirculating ball bearing

system, these rails ensure exceptional accuracy, high-speed

capability, and long-term reliability. Ideal for CNC machinery,

semiconductor manufacturing, and robotic systems, they minimize

energy loss while maintaining rigidity under dynamic loads. Key Characteristics Recirculating Ball System High-Speed Performance Rigid Load Support Preload Adjustability Corrosion-Resistant Options

Working Theory

Ball linear guides operate via a recirculating ball mechanism. The

carriage houses multiple rows of high-grade steel balls that roll

along precision-machined raceways on the rail. As the carriage

moves, the balls continuously cycle through return channels,

ensuring consistent contact and load distribution. Preload

adjustments compress the balls slightly against the raceways,

removing internal clearance to enhance stiffness and positional

accuracy. Integrated wipers and grease retainers prevent

contaminant ingress, while lubrication grooves ensure even oil

distribution.

| Series | Installation | Dimensions of the block | Dynamic | Static | | Size | dim.[mm] | [mm] | loadCdyn[N | load Co[N] | | H | W | B | C | L1 | L | M×1 | | RGH25CA | 40 | 48 | 350 | 35 | 645 | 979 | M6×8 | 27700 | 57100 | | RGH25HA | 40 | 48 | 350 | 50 | 810 | 1,144 | M6×8 | 33900 | 73400 | | RGH30CA | 45 | 60 | 400 | 40 | 710 | 1,098 | M8×10 | 39100 | 82100 | | RGH30HA | 45 | 60 | 400 | 60 | 930 | 1,318 | M8×10 | 48100 | 105000 | | RGH35CA | 55 | 70 | 500 | 50 | 790 | 1,240 | M8×12 | 57900 | 105200 | | RGH35HA | 55 | 70 | 500 | 72 | 1,065 | 1,515 | M8×12 | 73100 | 142000 | | RGH45CA | 70 | 86 | 600 | 60 | 1,060 | 1,532 | M10×17 | 92600 | 178800 | | RGH45HA | 70 | 86 | 600 | 80 | 1,398 | 1,870 | M10×17 | 116000 | 230900 | | RGH55CA | 80 | 100 | 750 | 75 | 1,255 | 1,837 | M12×18 | 130500 | 252000 | | RGH55HA | 80 | 100 | 750 | 95 | 1,738 | 2,320 | M12×18 | 167800 | 348000 | | RGH65CA | 90 | 126 | 760 | 70 | 1,600 | 2,320 | M16×20 | 213000 | 411600 | | RGH65HA | 90 | 126 | 760 | 120 | 2,230 | 2,950 | M16×20 | 275300 | 572700 |

| Series/Size | Installation dimensions [mm] | Dimensions of the block

[mm] | Dynamic

load Cdyn[NJ | Static

load Co[N] | | H | W | B | C | L1 | L | M | | RGW25CC | 36 | 70 | 57 | 45 | 645 | 979 | M8 | 27700 | 57100 | | RGW30CC | 42 | 90 | 72 | 52 | 710 | 1,098 | M10 | 39100 | 82100 | | RGW25HC | 36 | 70 | 57 | 45 | 810 | 1,144 | M8 | 33900 | 73400 | | RGW30HC | 42 | 90 | 72 | 52 | 930 | 1,318 | M10 | 48100 | 105000 | | RGW35CC | 48 | 100 | 82 | 62 | 790 | 1,240 | M10 | 57900 | 105200 | | RGW35HC | 48 | 100 | 82 | 62 | 1,065 | 1,515 | M10 | 73100 | 142000 | | RGW45CC | 60 | 120 | 100 | 80 | 1,060 | 1,532 | M12 | 92600 | 178800 | | RGW45HC | 60 | 120 | 100 | 80 | 1,398 | 1,870 | M12 | 116000 | 230900 | | RGW55CC | 70 | 140 | 116 | 95 | 1,255 | 1,837 | M14 | 130500 | 252000 | | RGW55HC | 70 | 140 | 116 | 95 | 1,738 | 2,320 | M14 | 167800 | 348000 | | RGW65CC | 90 | 170 | 142 | 110 | 1,600 | 2,320 | M16 | 213000 | 411600 | | RGW65HC | 90 | 170 | 142 | 110 | 2,230 | 2,950 | M16 | 275300 | 572700 |

|