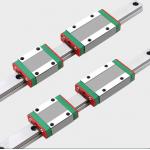

High Precision Heavy Load Linear Guide Rails Low Friction Corrosion

Resistant SEXGL Linear Guide Rails deliver unparalleled accuracy and durability in

high-precision automation systems, trusted by global leaders like

BYD (EV powertrain assembly) and BOE (LCD panel cutting robots)

across North America, Europe, Southeast Asia, and South

Korea.Linear guide rails are high-precision mechanical components

designed to enable smooth, friction-reduced linear motion in

industrial machinery and automation systems. These rails consist of

a hardened steel track paired with a carriage (or slider) equipped

with ball bearings or rollers, ensuring minimal resistance during

movement. Widely used in CNC machines, robotics, 3D printers, and

assembly lines, linear guide rails enhance accuracy, repeatability,

and load-bearing performance in dynamic applications. Key Characteristics High Rigidity & Load Capacity: Engineered with hardened steel, the rails withstand heavy loads

(up to 20,000 N static load capacity) without deformation. Precision Engineering: Ultra-fine grinding processes ensure tolerances as tight as

±0.005 mm/m for flawless alignment. Low Friction & Smooth Motion: Recirculating ball bearings or rollers reduce friction by up to

90% compared to traditional sliding systems. Corrosion Resistance: Optional stainless steel or coated variants for harsh

environments (e.g., food processing, marine). Modular Design: Supports customization in length, preload levels, and sealing

options for dust/liquid protection.

Working Theory

Linear guide rails operate on the principle of rolling contact

mechanics. The carriage houses multiple rows of precision balls or

rollers that circulate within a closed-loop raceway as the carriage

moves along the rail. This design converts sliding friction into

rolling friction, drastically reducing energy loss and wear.

Preload adjustments ensure optimal contact between rolling elements

and raceways, eliminating backlash and enhancing positional

accuracy. Lubrication channels and seals maintain long-term

performance by minimizing contamination. Details | Series | Installation | Dimensions of the block | Dynamic | Static | | Size | dim.[mm] | [mm] | load Cdyn[N] | load Co[N] | | H | W | B | c | L1 | L | M×1 | | HGH15CA | 28 | 34 | 260 | 26 | 394 | 614 | M4×5 | 11380 | 16970 | | HGH20CA | 30 | 44 | 320 | 36 | 505 | 775 | M5×6 | 17750 | 27760 | | HGH20HA | 30 | 44 | 320 | 50 | 652 | 922 | M5×6 | 21180 | 35900 | | HGH25CA | 40 | 48 | 350 | 35 | 580 | 840 | M6×8 | 26480 | 36490 | | HGH25HA | 40 | 48 | 350 | 50 | 786 | 1,046 | M6×8 | 32750 | 49440 | | HGH30CA | 45 | 60 | 400 | 40 | 700 | 974 | M8×10 | 38740 | 52190 | | HGH30HA | 45 | 60 | 400 | 60 | 930 | 1,204 | M8×10 | 47270 | 69160 | | HGH35CA | 55 | 70 | 500 | 50 | 800 | 1,124 | M8×12 | 49520 | 69160 | | HGH35HA | 55 | 70 | 500 | 72 | 1,058 | 1,382 | M8×12 | 60210 | 91630 | | HGH45CA | 70 | 86 | 600 | 60 | 970 | 1,394 | M10×17 | 77570 | 102710 | | HGH45HA | 70 | 86 | 600 | 80 | 1,288 | 1,712 | M10×17 | 94540 | 136460 | | HGH55CA | 80 | 100 | 750 | 75 | 1,177 | 1,667 | M12×18 | 114440 | 148330 | | HGH55HA | 80 | 100 | 750 | 95 | 1,558 | 2,048 | M12×18 | 139350 | 196200 | | HGH65CA | 90 | 126 | 760 | 70 | 1,442 | 2,002 | M16×20 | 163630 | 215330 | | HGH65HA | 90 | 126 | 760 | 120 | 2,036 | 2,596 | M16×20 | 208360 | 303130 |

| Series | Installation | Dimensions of the block | Dynamic | Static | | Size | dim.[mm] | [mm] | load Cdyn[NJ | load Co[N] | | H | W | B | C | L1 | L | M | | HGW15CC | 24 | 47 | 380 | 30 | 394 | 614 | M5 | 11380 | 16970 | | HGW20SC | 30 | 63 | 530 | 一 | 295 | 543 | M6 | 12190 | 16110 | | HGW20CC | 30 | 63 | 530 | 40 | 505 | 775 | M6 | 17750 | 27760 | | HGW20HC | 30 | 63 | 530 | 40 | 652 | 922 | M6 | 21180 | 35900 | | HGW25CC | 36 | 70 | 570 | 45 | 580 | 840 | M8 | 26480 | 36490 | | HGW25HC | 36 | 70 | 570 | 45 | 786 | 1,046 | M8 | 32750 | 49440 | | HGW30CC | 42 | 90 | 720 | 52 | 700 | 974 | M10 | 38740 | 52190 | | HGW30HC | 42 | 90 | 720 | 52 | 930 | 1,204 | M10 | 47270 | 69160 | | HGW35CC | 48 | 100 | 820 | 62 | 800 | 1,124 | M10 | 49520 | 69160 | | HGW35HC | 48 | 100 | 820 | 62 | 1,058 | 1,382 | M10 | 60210 | 91630 | | HGW45CC | 60 | 120 | 1,000 | 80 | 970 | 1,394 | M12 | 77570 | 102710 | | HGW45HC | 60 | 120 | 1,000 | 80 | 1,288 | 1,712 | M12 | 94540 | 136460 | | HGW55CC | 70 | 140 | 1,160 | 95 | 1,177 | 1,667 | M14 | 114440 | 148330 | | HGW55HC | 70 | 140 | 1,160 | 95 | 1,558 | 2,048 | M14 | 139350 | 196200 | | HGW65CC | 90 | 170 | 1,420 | 110 | 1,442 | 2,002 | M16 | 163630 | 215330 | | HGW65HC | 90 | 170 | 1,420 | 110 | 2,036 | 2,596 | M16 | 208360 | 303130 |

|