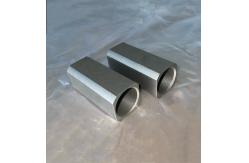

Precision CNC Machining Seamless Rectangular Tubes / Round Hole Steel Tubes

|

|

CNC precision machining of seamless square tubes/round hole steel tubes

Product Description We specialize in high-precision CNC machining of seamless thick-walled steel tubes with outer square and inner round profiles, designed for structural, mechanical, and industrial applications. Our advanced machining capabilities ensure tight tolerances, superior surface finishes, and complex geometries for custom tube components.

Key Features & Benefits✔ Premium Material Selection

✔ Precision CNC Machining Capabilities

✔ Machining Services

✔ Customization & Rapid Prototyping

✔ Quality Assurance

Product parameters :

1. Basic Parameters

2. Machining Capabilities

3. Performance & Testing

4. Customization & Logistics

Applications

Why Choose Us? ✅ Advanced CNC Equipment – Multi-axis machining centers

& lathes |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Precision Machining Seamless Rectangular Tubes CNC Machining Seamless Rectangular Tubes CNC Round Hole Steel Tubes |

|

Precision CNC Machined Parts - Heavy-Duty Truck Bolts, Hex Nuts & Automotive Components |

|

CNC Machined Truck Hinges – Heavy-Duty Door Components & Automotive Spare Parts |

|

Professional OEM Precision CNC Machining Services For Aluminum & Stainless Steel Parts |

|

Custom CNC Machined Parts For Outdoor Hiking Flashlight Shells |

|

CNC Machined High-Strength Alloy Steel Clutch Bearing Support Components |

|

Custom Stainless Steel Pinion Shafts, Gearboxes, Reducer Shafts & Precision CNC Machined Parts |