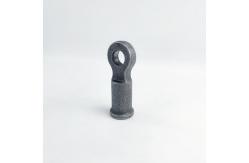

Forged End Accessories For Galvanized Steel Composite Insulators

|

|

Durable Forged End Accessories for Galvanized Steel Composite Insulators

Description :

Key Features :

Technical Parameters

Product application : These high-strength forged end fittings are critical components designed for use with galvanized steel composite insulators in various electrical and infrastructure applications. Their robust construction and corrosion-resistant properties make them ideal for:

1. Overhead Transmission & Distribution Lines

2. Substations & Switchgear

3. Railway Electrification Systems

4. Renewable Energy Projects

5. Industrial & Harsh Environments

Key Advantages for These Applications : ✔ Longevity: Galvanization prevents rust in humid/coastal

climates.

Why Choose Our Forged End Accessories?

|

|||||||||||||||||||||||||||||||||||||||

| Product Tags: Forged End Accessories Composite Insulators Forged Accessories Galvanized Steel Composite Insulators Parts |

|

High-Performance Forged Carbon Alloy Steel Roller Shafts – Industrial-Grade Custom Spindles |

|

Industrial Conveyor Chain Forged High Tensile Force Embedded Scraper Chain |

|

Precision Straight Axle Trailer Steel Forging Parts Custom |

|

Carbon Steel Forged Pipe Fittings For Pipe Connections |

|

Precision Carbon Steel Forging Parts Galvanized Cable Hooks U Shaped Automotive Fasteners |

|

Customized Carbon Steel Forging Pipe Fittings For Secure Connections |