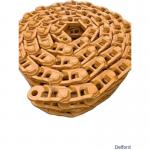

Excavator Track Link Assembly Abrasion Resistant Construction

Machine Wear Resistant Part

Product Description

The excavator track link assembly is a fundamental component of any

crawler-type construction machine's undercarriage system. These

critical parts form the backbone of the track chain, enabling the

machine's mobility and supporting its immense weight during

demanding operations. Our track link assemblies are specifically

engineered to deliver superior performance and unwavering

reliability in the most challenging work environments, ensuring

continuous productivity on your job site.

A paramount feature of our track link assemblies is their

exceptional abrasion and wear resistance. This characteristic is

achieved through a meticulous manufacturing process that utilizes

high-grade, specially selected alloy steels. These robust materials

undergo advanced heat treatment processes, including precision

induction hardening, which significantly enhances the surface

hardness and core toughness of each individual link. This

sophisticated metallurgical treatment provides outstanding

resilience against abrasive elements such as rock, sand, gravel,

and other harsh terrain encountered during heavy excavation,

mining, and earthmoving operations. The result is a component that

withstands prolonged friction and impact without compromising its

structural integrity or operational efficiency.

The superior wear resistance directly translates into an extended

service life for the entire undercarriage system. By effectively

resisting degradation from constant friction and impact, our track

link assemblies reduce the frequency of replacements, leading to

significant cost savings in maintenance and drastically reduced

operational downtime. Each link is meticulously forged and

precisely machined to strict international industry standards,

ensuring exact dimensional accuracy and a perfect fit with other

undercarriage components like track pins, bushings, and track

shoes. This precision fit minimizes undesirable play and stress

within the track system, further contributing to the longevity and

smooth, stable operation of your heavy equipment.

Designed for a broad range of excavator models and other

crawler-based heavy machinery, these track link assemblies are

built to perform consistently under extreme loads and in

challenging geological conditions. Whether your equipment is

engaged in deep digging, trenching, material handling, demolition,

or general site preparation, the robust construction and advanced

material properties of our links provide the necessary stability,

durability, and traction. They are an indispensable replacement

part for ensuring your excavator or other crawler-based heavy

equipment maintains optimal operational efficiency, safety, and

consistent performance in the toughest jobs.

Investing in high-quality, wear-resistant track link assemblies is

crucial for maximizing the overall value and long-term productivity

of your construction machinery fleet. Our products undergo rigorous

quality control inspections throughout the entire production cycle,

from raw material sourcing and initial forging to final machining

and assembly. This comprehensive commitment to quality guarantees

that each unit meets stringent performance and durability criteria

before it reaches our customers. This assurance of quality

translates to a reliable component that will withstand the test of

time, significantly reducing the likelihood of unexpected failures

and contributing to a lower total cost of ownership for your heavy

machinery assets.

We offer a comprehensive range of track link assemblies compatible

with various major excavator and bulldozer brands and models. Our

experienced team is ready to assist you in selecting the correct

part for your specific machinery and operational requirements.

Contact us today for detailed product specifications, customization

options for unique applications, or to discuss bulk purchasing

opportunities. We are dedicated to providing durable, efficient,

and cost-effective undercarriage solutions for all your heavy

machinery needs.