LD60 Three-Roller steel rolling mill for seamless pipe

|

|

Quick Detail:

Type: steel rolling mill Brand name: Hengli Model number: LD60 Input material: common carbon steel, alloy, nonferrous metal After-sales service provided: overseas service available Place of Origin: Jiangsu, China (Mainland) Used in: the field of Carbon pipes, Non-ferrous metal pipes, and so on.

Description:

Applications:

LD60 three-roller steel cold rolling mill is applicable to state rolling,such as carbon steel,alloy steel,stainless steel,non-ferrous metal,rare metal and so on,with the characteristics of good turnoff precision,high surface roughness ect.

Specifications:

Competitive Advantage:

We provides custom designed solutions on pilger mills and tube reducers. Our true value is in our expertise in engineering designs through active tri-matrix software and then constructing these designs using our 15+ years of production & maintenance experience. We pride ourselves in offering good engineering solutions to your tube manufacturing process with a commitment to customer satisfaction. Our global customer base covers all alloys such as aluminum, stainless steel, copper, titanium, zirconium, gold, silver, platinum, palladium, and other special alloy materials.

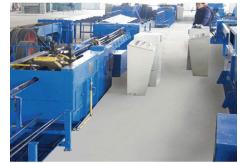

Reference photos for main equipment:

Certification:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: steel rolling mill machinery two high rolling mill |

|

LD20 Three Roller Steel Rolling Mill For Seamless Tube Making 22mm |

|

Mini Rebar Steel Rolling Mill Small Hot 114mm High Roughness |

|

Rebar Hydraulic 5 Roller SS Cold Rolling Mill For Thickness Reduction |

|

680mm Skin Pass Carbon Steel Rolling Mill Hydraulic Bending |

|

OD 108mm Seamless Nonferrous Cold Reduction Metal Rolling Mill |

|

100m/Min precision seamless Steel tube pipe Rolling Mill |