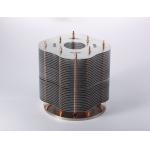

Projector High dssipation Aluminum Copper Pipe Heatsink Finned Heat Sink Electronic Heat Sinks

|

|

Projector High dssipation Aluminum Copper Pipe Heatsink Finned Heat Sink Electronic Heat Sinks

Quick Details:

Precision Copper Pipe Heat SInk Large Image: Aluminum Fin Heat Sink with Copper Pipe Materials: Pure Copper C1100 Strips, Purity over 99.5% Depend on customer's requirements

Description:

Large Image: Aluminum Fin Heat Sink with Copper Pipe 150W Big Power Copper Pipe Heat Sink Copper Pipe Heat Sink for Projector Heat Sink With Copper Pipe For Projector

Application: Projector, Computer, Cpu

Specification:

Copper processing:

Stamping

Automatic Tube Forming Machining

Overflow Welding/Drying Machine

Processing Technic:

1. Copper Fins: Progressive Die Stamping 2. Aluminum Board: Extrusion+ CNC Machining 3. Copper Tube Forming : Automatic Tube Bending+ Burn into Tip Ends. 4. Aluminum Board and Enclosure Nickle Plated, Copper Fin Passivate (Insulation, Oxidation and Corrosion Resistance). 5. Assembly: Automatic Fin Wearing/Assembly, then Fixed by Overflow Soldering and Screw/Rivet Combination. 6. Quality Check 7. Packing

Advantages:

1. Professional Research and Design Team, Strong & Automatic Equipments: Progressive Stamping, Automatic Tube Bending Machine, Automatic Fin Wearing Machining 2. Strict Quality Control in Each Process and Finish Product Quality Control 3. Short Delivery Lead Time: 15-30 Days 4. Optional For OEM or ODM 5. Comprehensive After-Sale Service, Quick Responses For Daily Communication |

||||||||||||||||

| Product Tags: pin fin heat sink extrusion heat sink |

|

Black Anodize Copper Pipe Heatsink 0.4mm Aluminum Fin Thickness |

|

Forging Copper Pipe Heat Sink +/-0.01mm Tolerance Customized Heat Pipe Diameter 8mm |

|

OEM/ODM Copper Tube Heat Sink For Computer CPU PC Application |

|

Customized Copper Pipe Heat Sink With Soldering Process And Anti Anodizing Finishing |

|

Custom Copper Pipe Heatsink With 0.4mm Aluminum Fin Thickness |

|

Anti Anodizing Copper Heat Pipe Heatsink High Power With Aluminum Plate |