3KW Battery Testing Equipment , 1000A Temperature Controlled External Short Circuit Tester

|

|

Battery Test Equipment of Temperature Controlled External Short Circuit Tester

Standard

It is conforms to IEC62133 clause 7.3.2 ,8.3.1,8.3.2 IEC60086-4 clause 6.5.1 IEC60086-4 clause 6.5.8 6.5.9 ,IEC 60086-1 ,IEC61951,IEC61960, UN38.3 ,UL1642, UL2054, QC 743/744, MT/T 1051-2007,GB/T 2900.11-1988,GB31241-2014and etc.

Technical Parameters

Product information

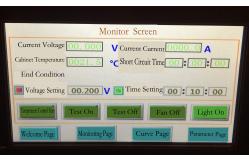

It is designed according to multi type battery short circuit standard requirements,in the standard requirement,the short circuit device must conform to the range of internal resistance ≤5mΩ, to obtain the maximum short-circuit current required by the test, In addition, the circuit design of the short-circuit device must also be able to withstand the impact of large currents, so we have chosen industrial grade DC electromagnetic contactors and all-copper terminals and internal copper plate diversion, thick copper plate to effectively improve the cooling effect, so that a large current short circuit device is safer, effectively reducing the loss of test equipment and ensuring the accuracy of test data. It is consist of high current contactor,remote controller, voltmeter, ammeter etc.

Features

1. High Current Contactor (1)Long distance connect and disconnect DC voltage to 220V. (2)Rated working current 1000A,installed with series connection magnetic blow mediastinal plate clay arc shield arc extinguishing system. (3)Plane layout structure, electromagnetic system and machine contactor arc extinguishing system fixed on under frame independently. Adopt angular rotation clapper type electromagnetic system and double winding attracting coil , add arris pressing device on the rotating angular. Main contactor made with red copper. With low contact resistance , high reaction speed (4)Reliable contactor acting, safety, long service life, and easy repair and maintenance. 2. Remote Controller (1)Long distance wireless control; (2)Reliable and stable work,with auto- locking and interlocking function, strong anti-interference ability, long service life. 3. Voltmeter (1)Measuring voltage:0-100V,ensure testing accuracy; (2)Display accuracy:F.S ±0.2% rdg ±1digit; (3)Drive method:double integral method 4. Ammeter (1)Measuring current:0-1000A and 0-500A DC; (2)Display Accuracy:F.S±0.2% rdg±1digit; (3)Drive method:double integral method

Accessories

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: battery test chamber battery discharge test equipment |

|

Minimum Detection Accuracy 1.0E-7mbar*L/s Helium Leak Detector For Automotive Battery Casing Battery Testing Equipment |

|

15KW Helium Leak Detector For Automotive Battery Casing For 0-0.5Mpa Battery Testing Equipment |

|

1.44E-4 mbar.l/s Battery Pack Suction Gun Helium Leak Detector for Battery Testing Equipment |

|

AC And DC Three Phase Variable Frequency Power Supply VP-20KVA Battery Testing Equipment |

|

180s/pc Battery Testing Equipment For EV Lithium Battery Pack Sniffer Helium Leak Test |

|

RS232 Battery Testing Equipment Leak Testing Of Battery Pack With Sniffing System |