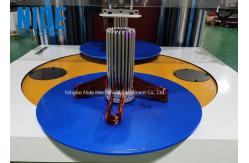

Induction 8 Stations Motor Stator Winding Machine Customized

|

|

Automatic Induction motor Stator winding machine coil winder customized

The winding machine is a device that winds a wire-like object onto a specific workpiece, and is usually used for copper wire winding. Most electrical products need to use enameled copper wire (referred to as enameled wire) to be wound into inductive coils, which can be completed by a winding machine or multiple processes.

Stator winding machine is a very important machine in automated motor manufacturing. NIDE Group can supply various motor manufacturing machines, provide different types of motor manufacturing solutions. Induction motor stator winding machines mainly include double-head winding machine, six-head 12-station winding machine, and four-head eight-station winding machine.

These stator winding machines are mainly composed of a winding part, a manipulator part, a film sinking part, and a turntable part. 1) Winding part: The main function is to wind the wire forward or backward on the wire cup. 2) Manipulator part: The main function is to guide the thread during the winding process, and to clamp or trim the thread after the winding is completed. 3) Film sinking part: The main function is to move the mold up and down instantaneously during the winding process to form a multi-layer winding effect. 4) Turntable part: The main function is to rotate the wire cup after the end of one cycle of winding according to the set index value, and to control the rotation of the turntable when the winding starts.

Stator winding machine process 1. The turntable rotates, the cupping axis rotates, and the manipulator reaches the winding position. 2. A section of the film sinks, winding starts, and the machine receives the pay-off position. 3. The manipulator waits at the position of clamping or cutting. 4. At the end of winding, the sinking axis will reach the final sinking position. 5. The machine uses the hand to finish the thread clamping action or the thread trimming action. 6. The film sinking axis returns to a section of film sinking position, and the cupping axis turns to the next indexing, knowing the last indexing

Technical paramenter

The stator winding machine video

|

||||||||||||||||||||||

| Product Tags: 8 stations motor stator winding machine vertical motor stator winding machine vertical single stator automatic winding machine |

|

Automatic Three Pin Linear Stator Coil Winding Machine |

|

Automatic E Bike Hub Motor Winding Machine With 2 Station Flyer Coil Wider |

|

Automatic 3 Needles Coil Winding Machine For BLDC Motor |

|

2 Stations Wheel Hub Motor Stator Winding Machine Automatic Self Balance Scooter |

|

Automatic BLDC Wheel Hub Motor Winding Machine For Electric Motorcycle |

|

8 Stations Automatic Motor Winding Machine Stator Coil Winder |