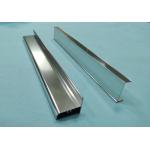

Detailed Product Description Product Name: | Mirror Aluminium | Alloy: | 6063,6060,6463 |

Material :

|

Aluminium Alloy |

Surface Treatment: | Bright Dip | Deep Process : | Milling, Drilling ,Bending, Cutting | Temper: | T5,T6,T66 |

Standard Mirror Surface Aluminum Shower Room Frame For Decoration

Order,payment,terms,shipment

1, Minimum order: 500kg per item and 1 ton per color, sample will

be sent for customer free of charge provided by approval and kept

for future mass production.

2, Sample Lead Time: working days(15 days for making the tool and

10 days making the samples. Before sending the samples to customer,

samples should pass strict test in our lab. )Production Lead time:

it depends on customers' order quantity ( 30 working days after

deposit).

3, Payment: 30% upon order confirmation and balance before delivery

by T/T

4, Tooling:100% prepaid by T/T.

Material | 6000 series Aluminium | Temper | T4, T5, T6 | Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or

customized available; Anodize protection film thickness from 8~25

um, powder coating from 40 ~ 120 um. | Shape | square, round, rectangular, customized | Application | In furniture, windows&doors, decorations ,industry,

construction and so on | Surface treatment | powder coating, electrophoresis, wood grain , anodized and so

on | Colors | Ref powder coating color sheet and customized color available | Deep process | CNC, drilling, milling, cutting, welding, bending, assembling | MOQ | 500kgs for each item | Packing Details | (1)Inside : packed with plastic protective film to protect each

piece | (2) Outside: Wrap to be bundles by waterproof craft paper | Delivery time | (1)Die Developing and Sample testing: 12-18 days . | (2) Mass Production completed: 20-30days after sample is confirmed

by Buyer. | FOB Port | SHENZHEN / GUANGZHOU / FOSHAN |

Primary Technical Data

1) Chemical composition Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | 6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | 6060 | 0.3~0.6 | 0.35~0.60 | 0.1~0.3 | ~ | <0.10 | <0.15 | <0.05 | ~ | 6463 | 0.2~0.6 | 0.45~0.90 | <0.15 | <0.20 | <0.05 | <0.05 | ~ | ~ | 6005 | 0.6~0.9 | 0.40~0.60 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 | 6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 | 6082 | 0.7~1.3 | 0.60~1.2 | <0.50 | <0.1 | 0.4~1.0 | <0.20 | <0.25 | <0.10 | 6351 | 0.7~1.3 | 0.40~0.8 | <0.50 | <0.1 | 0.4~0.8 | <0.20 | ~ | <0.10 |

2) Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation | 6063

| T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% | T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% | 6061 | T5 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

|