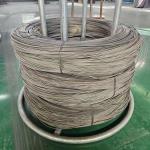

Fecr13al4 Alloy 125 Ferritic Alloy Fecral13/4 Wire For Water Heater

FeCrAl resistance electrothermal alloy has high

resistivity, good surface oxidation resistance , and high strength

at high temperature, good processing performance and weldability ,

can be widely used in gold , household appliances , machinery

manufacturing industry as heating elements and electrical industry

as resistance materials.

Chemical Composition

| GRADE | Chemical Composition |

| Cr | P | S | Mn | Si | Cr | Ni | Al | Fe |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | 5.0-7.0 | 4.5-5.3 | Rest |

Applications of FeCrAl:

| Application | Advantages |

| Automobile and motorcycle exhaust purification metal honeycomb

carrier | Uniform chemical composition, high resistivity, long service life. |

| Locomotive starting and brake resistor |

| Temperature detection, drilling oil field brake resistor |

| Grounding resistance cabinet for central point of power system |

| Cement resistance, sealing machine, diamond,electronic industry and

all kinds of ignition and heating electrode and motor voltage

regulator |

| Chemical

Composition and Main Property of Fe-Cr-Al Resistance Alloy |

Properties Grade

| 1Cr13Al4

| 0Cr25Al5

| 0Cr21Al6

| 0Cr23Al5

| 0Cr21Al4

| 0Cr21Al6Nb

| 0Cr27Al7Mo2

|

Main Chemical Composition

(%)

| Cr

| 12.0-15.0

| 23.0-26.0

| 19.0-22.0

| 22.5-24.5

| 18.0-21.0

| 21.0-23.0

| 26.5-27.8

|

Al

| 4.0-6.0

| 4.5-6.5

| 5.0-7.0

| 4.2-5.0

| 3.0-4.2

| 5.0-7.0

| 6.0-7.0

|

Re

| opportune

| opportune

| opportune

| opportune

| opportune

| opportune

| opportune

|

Fe

| Bal.

| Bal.

| Bal.

| Bal.

| Bal.

| Bal.

| Bal.

|

|

|

|

|

|

| Nb0.5

| Mo1.8-2.2

|

Max Continuous Service Temperature(oC)

| 950

| 1250

| 1250

| 1250

| 1100

| 1350

| 1400

|

Resisivity 20oC (Ωmm2/m)

| 1.25

±0.08

| 1.42

±0.06

| 1.42

±0.07

| 1.35

±0.07

| 1.23

±0.07

| 1.45

±0.07

| 1.53

±0.07

|

Density(g/cm3)

| 7.4

| 7.1

| 7.16

| 7.25

| 7.35

| 7.1

| 7.1

|

Thermal Conductivity

| 52.7

| 46.1

| 63.2

| 60.2

| 46.9

| 46.1

| 45.2

|

(KJ/m@h@oC)

|

Coefficient of Thermal Expansion(α×10-6/oC)

| 15.4

| 16

| 14.7

| 15

| 13.5

| 16

| 16

|

Approximate Melting Point( oC)

| 1450

| 1500

| 1500

| 1500

| 1500

| 1510

| 1520

|

Tensile Strength(N/mm2)

| 580-680

| 630-780

| 630-780

| 630-780

| 600-700

| 650-800

| 680-830

|

Elongation(%)

| >16

| >12

| >12

| >12

| >12

| >12

| >10

|

Section Variation

| 65-75

| 60-75

| 65-75

| 65-75

| 65-75

| 65-75

| 65-75

|

Shrink Rate (%)

|

Repeatedly Bend Frequency(F/R)

| >5

| >5

| >5

| >5

| >5

| >5

| >5

|

Hardness (H.B.)

| 200-260

| 200-260

| 200-260

| 200-260

| 200-260

| 200-260

| 200-260

|

Continuous Service Time

| no

| ≥80/1300

| ≥80/1300

| ≥80/1300

| ≥80/1250

| ≥50/1350

| ≥50/1350

|

Micrographic Structure

| Ferrite

| Ferrite

| Ferrite

| Ferrite

| Ferrite

| Ferrite

| Ferrite

|

Magnetic Property

| Magnetic

| Magnetic

| Magnetic

| Magnetic

| Magnetic

| Magnetic

| Magnetic

|