Ferro-Chrome-Aluminum Resistance Wire A1 1.4mm For Automotive Industry

|

|

Hot Sales Ferro-Chrome-Aluminum Resistance Wire A1 1.4mm Used For Automotive Industry

The properties of FeCrAl alloy heating wire include high electrical resistivity, good oxidation resistance at high temperatures, and the ability to withstand high operating temperatures. These characteristics make them suitable for applications where stable and reliable heating is required under harsh conditions.

How does the composition of FeCrAl affect its properties?

The composition of FeCrAl alloy significantly affects its properties, making it suitable for various applications. Here's how the composition of FeCrAl alloy impacts its properties:

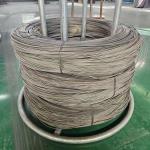

Package:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Ferro-Chrome-Aluminum Resistance Wire 1.4mm Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |