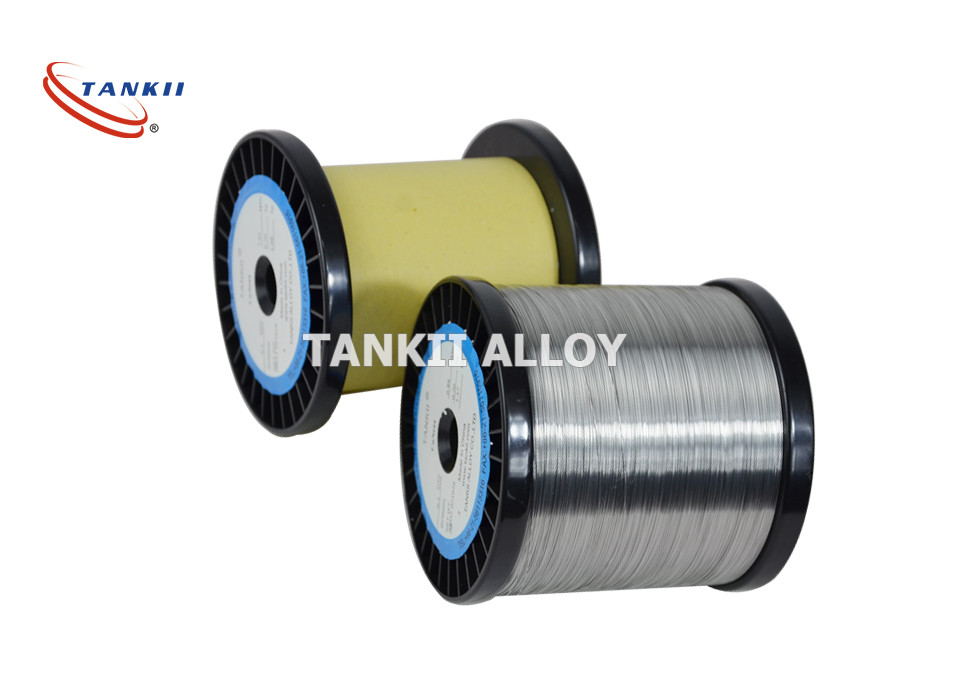

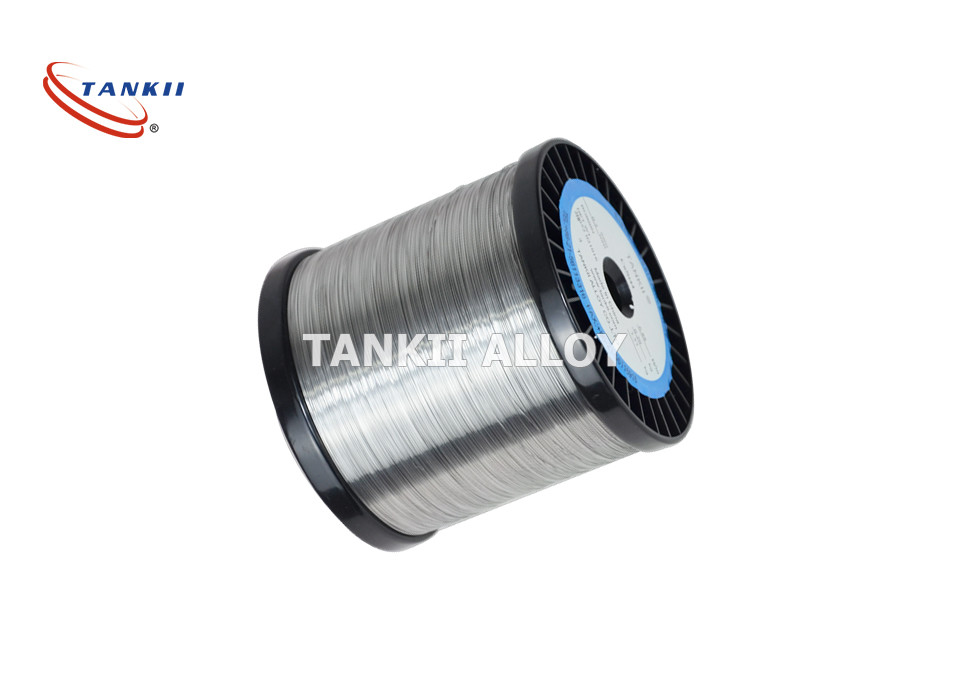

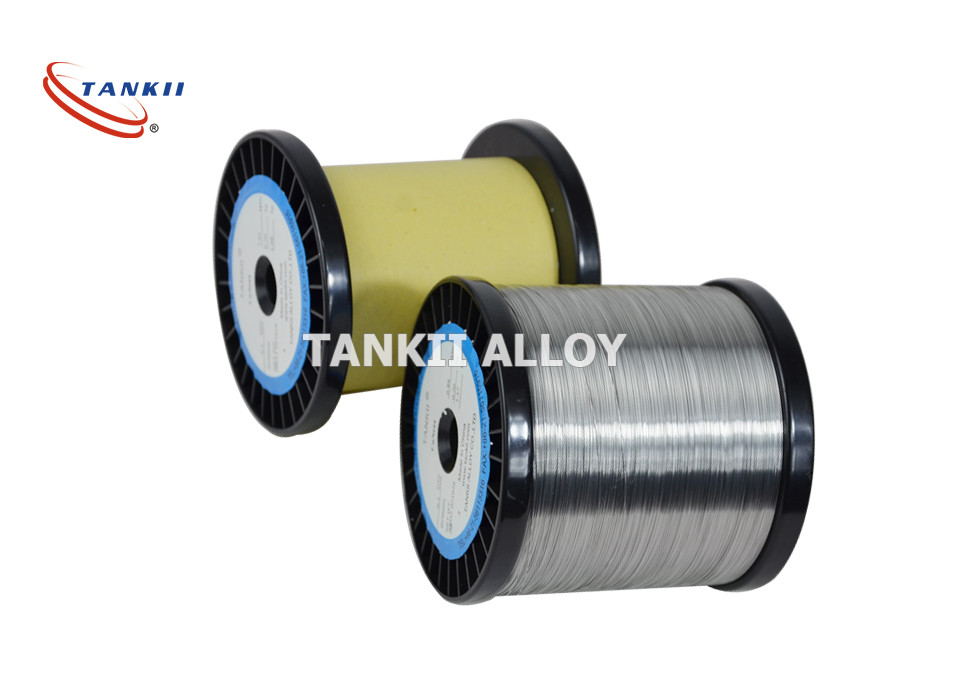

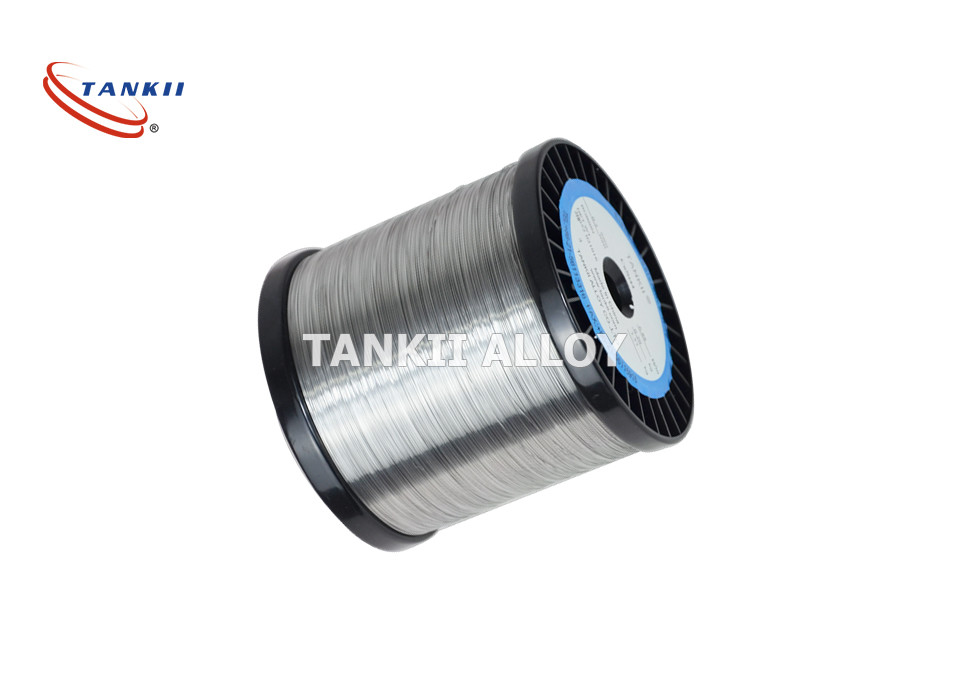

TANKII Precision/Electric/Nicr8020 Nichrome 0.32 Resistance Heating Wire Thermocouple Bare Wire for Heating Elements

Nickel-chromium alloy with high and stable resistance, corrosion resistance, surface oxidation resistance, excellent coil- forming ability.it is an ideal material,it has good ductility,workability and weldability under high temperature and seismic strength.

Common Name:Ni80Cr20,Nikrothal 8,MWS-650,NiCrA,Tophet A,HAI-NiCr 80,Chromel A,Alloy A,Alloy 650,N8,Resistohm 80, Stablohm 650,Nichorme V,Nikrothal 80.

Ni80Cr20 is a nickel-chromium alloy (NiCr alloy) characterized by high resistivity, good oxidation resistance and very good form stability. It is suitable for use at temperatures up to 1200°C,and hold a superior service life compared to Iron chromium alumium alloys.

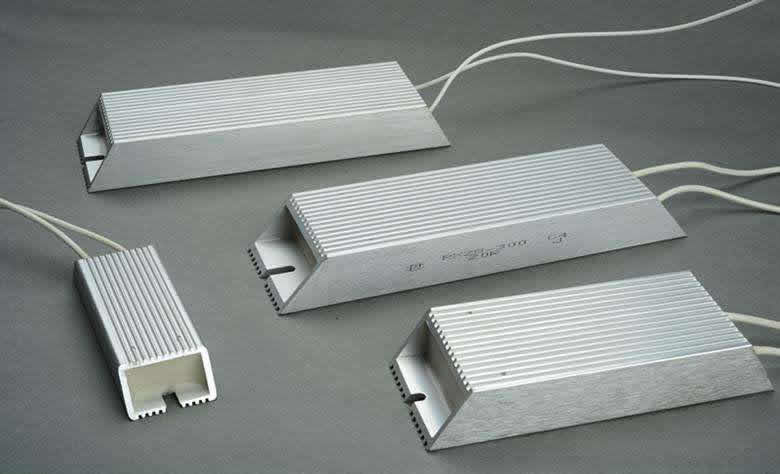

Typical applications for Ni80Cr20 are electric heating elements in home appliances,industrial furnaces and resistors(wirewound resistors,metal film resistors), flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements and cartridge elements. Mechanical Properties of Nichrome 80 wire | Max Continuous Service Temperature: | 1200ºC | | Resisivity 20ºC: | 1.09 ohm mm2/m | | Density: | 8.4 g/cm3 | | Thermal Conductivity: | 60.3 KJ/m·h·ºC | | Coefficient of Thermal Expansion: | 18 α×10-6/ºC | | Melting Point: | 1400ºC | | Elongation: | Min 20% | | Micrographic Structure: | Austenite | | Magnetic Property: | nonmagnetic | Temperature Factors Of Electrical Resistivity | 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | | 1 | 1.006 | 1.012 | 1.018 | 1.025 | 1.026 | 1.018 | | 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1200ºC | 1300ºC | | 1.01 | 1.008 | 1.01 | 1.014 | 1.021 | 1.025 | - | Style of supply | Alloys Name | Type | Dimension | | Ni80Cr20W | Wire | D=0.016mm~10mm | | Ni80Cr20R | Ribbon | W=0.3~5mm | T=0.01~2mm | | Ni80Cr20S | Strip | W=1~450mm | T=0.005~5.0mm | | Ni80Cr20B | Bar | Dia=3~100mm | L=50~3000mm | | Chemical Composition and Main Properties of Nichrome wire | | Properties Grade | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | | Main Chemical Composition | Ni | Balance | Balance | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 | | Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | | Fe | ≤ 1.0 | ≤ 1.0 | Balance | Balance | Balance | | Max Continuous Service Temperature(oC) | 1200 | 1250 | 1150 | 1100 | 1100 | | Resisivity 20oC (Ω mm2/m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | | Density (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | | Thermal Conductivity(KJ/m@ h@ oC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | | Coefficient of Thermal Expansion(α × 10-6/oC) | 18 | 17 | 17 | 19 | 19 | | Melting Point( oC) | 1400 | 1380 | 1390 | 1390 | 1390 | | Elongation(%) | > 20 | > 20 | > 20 | > 20 | > 20 | | Micrographic Structure | austenite | austenite | austenite | austenite | austenite | | Magnetic Property | nonmagnetic | nonmagnetic | nonmagnetic | Weak magnetic | Weak magnetic | | Chemical Composition | Nickel Chrome (Iron) Alloy | | Surface | Bright,Acid white,Oxidized Color | | Diameter | 0.016mm~2.0mm in spool, 1.0mm-8.0mm packing in coil, 3.0~100.0mm in rod | | Nichrome Round Wire | Diameter 0.016mm~10.00mm | | Nichrome Ribbon | Width: 5.00~0.30mm, thickness: 0.01-2.00mm | | Nichrome Strip | Width: 1mm~450mm, thickness: 0.005mm~5mm | | Grade | Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni60Cr23, Ni35Cr20,Ni40Cr20,Ni30Cr20, NiCr20AlSi, Karma | | Advantage | The metallurgical structure of nichrome | | confers them a very good plasticity when cold. | | Characteristics | Stable performance; Anti-oxidation; Corrosion resistance; | | High temperature stability; Excellent coilforming ability; | | Uniform and beautiful surface condition without spots. | | Usage | Resistance heating elements;Material in metallurgy, | | Household appliances;Mechanical manufacturing and | | other industries. | Key Features of nichrome products: - Nichrome 80 is a proven electrical resistance heating material

- Produces adherent chromium oxide layer to prevent oxidation

- Highly durable and corrosion resistant

- Ideal for use in frequent temperature switching application

2 Products and services

1> ROHS cerfication;

2.> Small orders are accepted;

3.> Factory direct sale;

4.> Timely delivery;

5> Samples are available;

3 Features

1>. Good oxidation resistance;

2> . Low embrittlement at high temperature;

3.> Good plasticity(easier to give them a shape);

4> . Nice performance and processing;

4 Applications

1> . In metal sheathed tubular elements used in grills;

2> . Toaster ovens;

3.> Storage heaters;

4.> As suspended coils in air heaters;

5.> Used in clothes dryers, fan heaters, hand dryers;

6> . Industrial hot wire foam cutters.

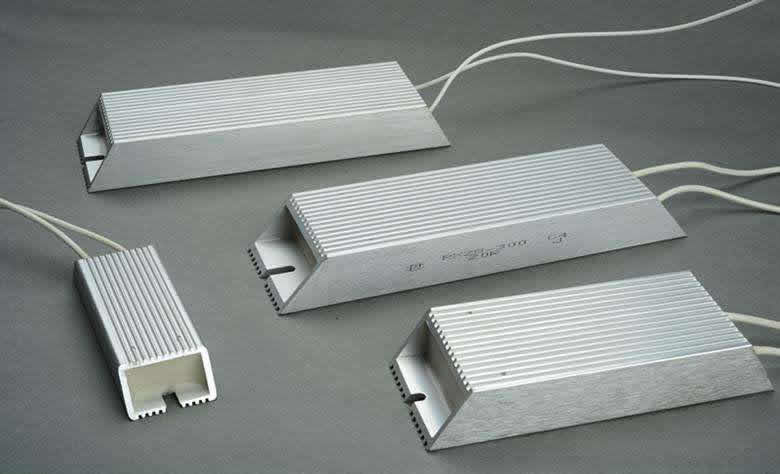

They are used for the manufacture of electric resistances for appliances (insulated elements type tubular resistances or for example opened elements on micanit plate) or for application of industrial furnaces.

In addition of a relatively high specific resistance, Ni-Cr alloys join all the necessary properties for good performances in use of furnaces: Resistance to oxidation (they are not sensitive to aggressions of humid air).

Mine trolley brake resistor:

|