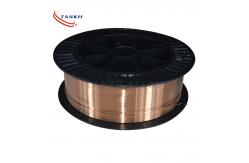

Ercual-A1 Aluminum Bronze Welding Wire For Tube Sheets Chemical Plants

|

|

ERCUAL-A1 ALUMINUM BRONZE WELDING WIRE For Welding Tube Sheets Valve Seats Pickling Hooks Impellers Chemical Plants

ERCUAL-A1 ALUMINUM BRONZE WELDING WIRE APPLICATIONERCuAl-A1 Aluminum Bronze Welding Wire is an iron-free, aluminum bronze alloy available in spooled wire and 36” bare-filler metal rod for use with the gas metal-arc and gas tungsten-arc welding processes respectively. ERCuAl-A1 Aluminum Bronze Welding Wire deposits are used primarily to overlay bearing and wear-resistant surfaces requiring a hardness of approximately 125 BHN and to resist corrosion especially from saltwater, metal salts, and many commonly used acids in varying concentrations and temperatures. This alloy is not recommended for joining since the deposit does not have a tendency to be hot short. ERCuAl-A1 Aluminum Bronze Welding Wire Aluminum Bronze Welding Wire applications include tube sheets, valve seats, pickling hooks, impellers, chemical plants, and pulp mills. ERCUAL-A1 ALUMINUM BRONZE WELDING WIRE PHYSICAL AND MECHANICAL PROPERTIES

|

||||||||||||

| Product Tags: Chemical Plants Aluminum Bronze Welding Wire Tube Aluminum Bronze Welding Wire Aluminum Bronze Thermal Spray Wire |

|

AWS 5.14 ERNiCr-3 Nickel Alloy Welding Wire for MIG TIG |

|

Tankii Edit NiCrTi/45CT Spray Wire In Arc And Flame Spray System |

|

Tankii Tungsten Carbide 97MXC Wear And Corrosion Resistance |

|

High Quality Inconel 625 ERNiCrMo-3 1.2mm |

|

Bright Surface Alloy Thermal Spray Wire Ta-Fa 75B/Ni95Al5/NiAl95/5 For Arc Spraying Flame Spraying |

|

1.6mm 2.0mm FeCrBSi 95mxc Coating Wire Arc Spraying Wire For Bolier Tubes And Tube Shields |