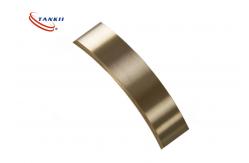

Qbe2 C17200 Harden Beryllium Copper Strip Polished 0.05mm

|

Detailed Product Description

|

Xhm (TM06) / Xhms (TM08) Harden Copper Alloy Strip beryllium Coper

Tape C17200 Qbe2 Strip Shanghai Tankii Alloy Material Co.,Ltd is the leader company in the

manufacture of beryllium-copper alloys. We actively participate in

all environmental studies made on all substances used in our

products. Our priority is to comply with all legal regulations in

force to ensure the continued existence of our products to our

clients. Beryllium-Copper-alloys are mainly based on copper with a beryllium

addition. High strength beryllium copper alloys contain 0.4-2% of

beryllium with about 0.3 to 2.7% of other alloying elements such as

nickel, cobalt, iron or Lead. The high mechanical strength is

achieved by precipitation hardening or age hardening. It is the best high-elastic material in copper alloy. It has high strength, elasticity, hardness, fatigue strength, low elastic hysteresis, corrosion resistance, wear resistance, cold resistance, high conductivity, no magnetism, no impact, no sparks, etc. A range of excellent physical, chemical and mechanical properties.

Physical Properties C17200

Mechanical property:(before heat treatment) C17200

Mechanical property:(after heat treatment) C17200

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Harden Beryllium Copper Strip Polished Beryllium Copper Strip Beryllium Copper Strip 0.05mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

0.02mm To 10mm FeCrAl Alloy Resistance Wire Used For Heating Elements (CrAl 25/5) |

|

Factory Polished Molybdenum Rod and Bar with >99.95% Purity for High Temperature Heating up to 2200ºC ASTM B386-91 Standard |

|

Nichrome Heating Wire Ni80Cr20 0.018mm-1.6mm Diameter |

|

Nickel 201 Alloy Wire UNS N02201 ASTM B160 B162 |

|

Ni80Cr20 Nichrome Alloy Flat Wire for High-Temperature Heating Elements |

|

Ni200 Ni201 Pure Nickel Wire 99.98% High Purity 0.025-10mm |

Email to this supplier