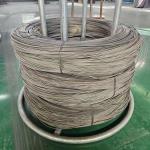

1Cr13al4 Alloy 750 Annealed Heating FeCrAl Wire Electric Resistance

|

Detailed Product Description

|

1Cr13al4 Alkro-thal 14 alloy 750 Bright and Annealed Heating Wire 1Cr13Al4 is an iron-chromium-aluminium alloy (FeCrAl alloy) for use

at temperatures up to 750°C (1382°F). The alloy with the

characteristics of high resistivity, low temperature coefficient of

electric resistance, high operating temperature, good oxidation

resistance under high temperature. It is widely used in industrial electric furnace, household electrical appliance and far infrared ray device. Such as panel heaters, infrared heaters, warming plates, in cartridge heaters, storage heaters, ceramic heaters for cooking plates, kilns elements, radiators, in quartz tube heaters for space heating, toasters, toaster ovens, industrial infrared dryers, coils on molded ceramic fibre for cooking plates with ceramic hobs and so on. FeCrAl,a family of iron-chromium-aluminum alloys used in a wide

range of resistance and high-temperature applications is also used

in the form of resistance wires. FeCrAl resistance electrothermal alloy has high resistivity, good surface oxidation resistance , and high strength at high temperature, good processing performance and weldability , can be widely used in gold , household appliances , machinery manufacturing industry as heating elements and electrical industry as resistance materials.

Chemical Content, %

Mechanical Properties

Temperature Factor of Electrical Resistivity

Feature: With long service life.Heating up fast.High thermal efficiency.Temperature uniformity. Can use vertically. When being used in the rated voltage,there is no volatile matter.It i the ne environmental protection electric heating wire.And an alternative to the costly nichrome wire.Can be customized according to customer requirements Usage: It is widely used in industrial furnace, household electrical appliances, infrared heater, etc. The key properties: 1.The thickness of surface insulation resistance to oxidation layer: 5-15 μ m. 2. Insulation resistance: multimeter detection infinity. 3.The voltage-endurance of insulating single layer is greater than the alternating voltage 60 ν without breakdown. 4. The use of voltage: 6-380 ν. 5. Using temperature: Maximum1200 ºC 6. Service life: not less than 6000 hours. 7.Thermal shock performance: Electric heating element can withstand the cold and hot impact 600-6000 times without deformation. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Annealed Heating FeCrAl Wire Alloy 750 FeCrAl Wire 1Cr13al4 FeCrAl Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |

Email to this supplier