Bright Annealed FeCrAl Heating Resistance Wire Oxidation Resistance

|

|

Product Description furnace fecral resistance heating wire Fe-Cr-Al Alloy Specification High quality Low Price FeCrAl Alloy Wire

Fe-Cr-Al alloy has the characteristic of high resistivity,low temperature resistance coefficient,high operating temperature,good anti-oxidation and anti-corrosion under high temperature.

It is widely used in industrial furnace, household appliances, industry furnace, metallurgy, machinery, aircraft, automotive, military and other industries producing heating elements and resistance elements.

nichrome heating alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

FeCrAl resistance wire grade: 0Cr25Al5, 1Cr13Al4, 0Cr23Al5, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al4, 0Cr21Al6.

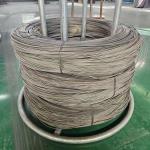

In the form of wire, ribbon and strip, one kind of material Fe-Cr-Al alloy.

Wire: 0.018mm-10mm Rod: 8mm-50mm Ribbon: 0.05*0.2mm-2.0*6.0mm

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: FeCrAl Heating Resistance Wire Bright Annealed Heating Resistance Wire Oxidation Resistance FeCrAl Alloy | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |