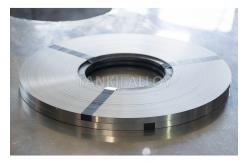

Cr14Al4 FeCrAl Alloy Fecral Heating Strip For Heat Element

|

Detailed Product Description

|

Iron Chromium Aluminium Alloys/strip

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Cr14Al4 FeCrAl Alloy Fecral Heating Strip Heat Element FeCrAl Alloy | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |

Email to this supplier