Electric Heat Resistant 0Cr15Al5 Fecral Wire For Furnace

|

|

0Cr15Al5 FeCrAl Electric Heating Resistance Alloy Wire for Furnace

Introduction

1)Alloy grades:

Chemical Composition (%)

Properties

Mesh Specification

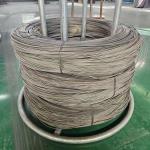

The manufacture of mesh is started with producing wire. The wire

production includes: forging, rolling, annealing and drawing. The

wire with right material and wire diameter will be produced. Then

the warp wires will be put and prepared on the weaving machine, and

then start weaving. From wire to mesh, manufacture process is

operated with high standard quality control system. There will be

quality test for each batch of product, such as test to diameter

tolerance, content, mesh aperture, etc. Packing Process & Transportation Packaging: Seal up, with plastic inside and wooden case or carton

outside; or according to the customer's requirements. Transportation: By air or By sea

|

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 0Cr15Al5 Fecral Wire Heat Resistant Fecral Wire Furnace Fecral Wire |

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |