High Temperature Heat Resistant Wire Kantha A1 Wire For Heating Resistor

|

|

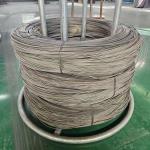

High Temperature Heating Resistance Wire Kantha A1 Wire Long Life Sweden Wire for Heating Resistor TK A-1 large-sized cold-drawn wire products can be used for high-temperature resistance furnace. Practice has proved that: the product process is stable, integrated performance is good. Has good high temperature oxidation resistance and longer service life; excellent winding properties at room temperature processing, ease of processing molding; little rebound resilience and so on. Processing performance is very good; operating temperature can reach 1400 ℃. Main specifications and uses:

Conventional Product specifications: 0.5 ~ 10 mm

Uses: mainly used in powder metallurgy furnace, diffusion furnace, radiant tube heater and all kinds of high-temperature furnace heating body.

MAIN CHEMICAL ELEMENTS AND PROPERTIES

User Manual

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: electrical heating wire high temperature wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |