Fecral 0cr21al6nb Flat Resistance Heating Strip With Iso9001 Certificate

|

Detailed Product Description

|

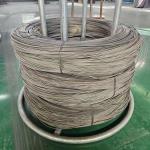

FeCrAl 0Cr21Al6Nb Alloy Strip Resistance Heating Flat Wire with

ISO9001 Certificate Introduction Resistance wire includes pure nickel, chromel alloy, Fe-Cr-Al alloy

and copper nickel alloy. Resistance heating wire is produced by smelting, steel rolling,

forging, annealing, drawing, surface treatment, resistance control

test, etc. It is widely used for making heating equipment like industrial

furnace, civil heating appliance, various electrical resistors and

locomotive braking resistor. Specification

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: high temperature wire electrical heating wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

FeCrAl Alloy Wire 0.6mm 1.2mm High Temperature Resistance Heating |

|

0Cr21Al6Nb FeCrAl Alloy Heating Wire 1250ºC Max Temp |

|

FeCrAl Alloy Wire 1Cr13Al4 High Resistance Heating Element |

|

FeCrAl Alloy Wire 0Cr25Al5 High Temperature Resistance Coil |

|

Hot Sale 0.1-10mm 1Cr13Al4 Fecral Alloy Electric Heating Wire |

|

FeCrAl Alloy 0Cr25Al5 Chemical Heating Wires Bright Surface |

Email to this supplier