Common Applications:

1.studios, recording rooms, listening rooms, rehearsal rooms and

more professionally interspace timbre projects.

2.theaters, indoor gymnasiums, discos, KTV rooms and more

performance and entertainment location.

3.meeting rooms, offices, halls, hotels and more sound absorption

and secrecy projects.

4.air-port, railways, bus-stops, workshops and more noise reduction

projects.

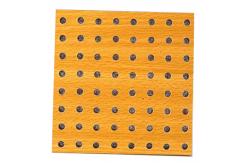

Product Description:

Perforated acoustic panel : BANGE perforated acoustic panel used high density mold- proof,

fireproof, enviromental eco-pine wood as base material, processed

by full automatic computer controled equipment. Be made to

multihole structures product, not only have good sound absorbing

effect, but also looks great on visual.

| Model type | E16/6,E32/6,V32/6,E35/1.5-10,V32/3-10 | | Size6 | 600*600,1200*600,2400*1200mm | | Thickness | 12,15,18mm | | Finish | melamine, veneer, metal finish, acrylic, PU leather, | | paint | UV,PU painting | | Base material | Standard MDF, Eco-pine wood MDF, Fireproof MDF, Moistureproof MDF,

Magnesium Composited MDF | | MDF density | 680kg/cubic meter | | Backside finish | acoustic felt, woven fabric | | Fireproof grade | GB8624 2012 A,B1,B2,B3 | | Eco-protection grade | E0,E1 | | Installation | aluminum keel and clips, wood frame, gun nail | | Backside hole diameter | 10 mm | | Depth of groove | 7mm | | Veneer type thickness | 0.3,0.6mm | | Veneer texture | Mountain texture, straight line | | Veneer tree species | Maple, cherry, Oak, teak, walnut, ashtree, sabelli, birch, | | Certification | BV,CE,SGS,ISO9001-2008, | | Test report | Eco protection, sound absorption, flame retardant |

Perforated wall panels performances:

Acoustic absorption is usually defined in terms of an absorption

coefficient(usually denoted by the Greek letter alpha, α), defined as the ratio of absorbed to

incident sound energy from a single interaction between a sound

wave and a certain material. Absorption coefficients range from 0

to 1 and vary with frequency, α=0 means that the material absorbs

no sound and reflects all sound energy incident on it.

α=1 means that the material absorbs all sound energy incident on it

and reflects none. Absorption coefficients of 0 and 1 are ideal values

that do not exist in reality because all materials reflect and

absorb some sound. In general, materials having absorption

coefficients less than 0.15 are considered to be reflective and

those having absorption coefficients greater than 0.4 are considered to be absorptive.

As you can see our Testing report show that our products have a

very good performance in a

large range of application.

Features:

1 Mdf soundproof acoustic board is a kind of resonance absorption

material with holes through on the quality MDF board.

2 It has strong selection on the sound spectrum and particular

great performance on the middle and low frequency.

3 If filled with the acoustic cotton at the back side space of the

acoustic panel, it has better performance on the middle and high frequency.

4 The holes diameter and pitch can be custom made.

5 Strong impact resistance, excellent decorate performance, elegant

color, especially work for wooden construction.

|