Fusible interlining is a type of fabric used in garment manufacturing to add

structure, reinforcement, and support to fabrics. It is a specially

treated material with an adhesive coating on one side that allows

it to bond with other fabrics when heat and pressure are applied.

Fusible interlining is widely used in various garment types, such

as shirts, jackets, collars, cuffs, and waistbands, providing them

with enhanced shape, firmness, and stability. Manufacturing Process of Fusible InterliningThe production of fusible interlining typically involves the

following steps: Fabric Selection: The base fabric, which can be woven or nonwoven, is chosen

depending on the specific requirements of the garment. Common

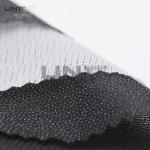

materials include cotton, polyester, or nylon. Adhesive Coating: A thermoplastic adhesive, typically in the form of powder or

film, is applied to one side of the fabric. This adhesive is the

key to the fusible property, allowing the interlining to bond with

the main fabric when heated. Heat Treatment: The fabric is subjected to a heat treatment process that ensures

the adhesive is evenly distributed and activated. This step ensures

that the interlining maintains its fusible properties during

garment production. Finishing: The fusible interlining is finished to achieve the desired

characteristics such as softness, flexibility, and strength. This

may include additional processes like calendaring, which smooths

the fabric, or steaming to enhance the adhesive's effectiveness.

Key Features of Fusible InterliningStrong Adhesion: The adhesive layer enables fusible interlining to bond firmly to

the fabric, providing long-lasting support and structure. Easy Application: Fusible interlining is easy to apply by simply using heat and

pressure, typically with an iron or pressing machine. This

convenience makes it ideal for large-scale garment production. Enhanced Durability: The fusible nature ensures that the interlining stays in place

even after multiple washes and wear, maintaining its integrity and

performance over time. Versatility: Fusible interlining comes in various weights, thicknesses, and

finishes, making it suitable for a wide range of garment types,

from lightweight blouses to heavy outerwear. Improved Shape and Structure: Fusible interlining helps maintain the desired shape of garments,

preventing sagging, wrinkling, or stretching, which improves the

overall appearance and longevity of the clothing. Comfort and Softness: Despite providing structure, fusible interlining remains soft and

flexible, ensuring that it does not compromise the comfort of the

garment.

Types of Fusible InterliningWoven Fusible Interlining: Made from woven fabrics, this type of fusible interlining offers

high stability and strength. It is often used for applications

where a crisp, structured finish is required, such as in shirts,

collars, and cuffs. Nonwoven Fusible Interlining: Produced from fibers that are bonded together, nonwoven fusible

interlining is more flexible and lightweight. It is ideal for use

in garments that require softness and drape, such as in dresses or

skirts. Lightweight Fusible Interlining: This type of interlining is thinner and more flexible, providing

a softer feel while still offering structure. It is typically used

in delicate fabrics that need minimal reinforcement. Heavyweight Fusible Interlining: Suitable for more rigid garments, this type of interlining

provides substantial structure and support. It is often used in

outerwear, jackets, and coats. Stretch Fusible Interlining: Stretch fusible interlining has the added advantage of

elasticity, making it suitable for knitwear or fabrics with a

stretch component. It allows the garment to retain its shape

without compromising the stretchability of the fabric.

Applications of Fusible InterliningShirts: Fusible interlining is commonly used in shirts, especially in

collars, cuffs, and plackets, to provide crispness and structure. Jackets and Coats: It is widely used in outerwear to add stability to areas like

lapels, waistbands, and the front panels, ensuring that the garment

maintains its shape. Skirts and Dresses: Fusible interlining helps in maintaining the shape of skirts,

dresses, and other structured garments while ensuring that the

fabric remains soft and comfortable. Trousers: In trousers, fusible interlining is often used in waistbands and

pockets to provide extra strength and support. Accessories: Fusible interlining is also used in the production of accessories

such as bags, belts, and hats, where added structure is required. Home Textiles: Fusible interlining is used in home textile products like

curtains, upholstery, and cushions to enhance the fabric's

durability and appearance.

Advantages of Fusible InterliningEasy to Apply: Fusible interlining eliminates the need for sewing or stitching,

simplifying the production process and saving time and labor costs. Durability: The adhesive bond created by fusible interlining ensures that it

stays in place throughout the garment's lifecycle, even after

frequent washing. Variety: Fusible interlining comes in different types, weights, and

finishes, giving manufacturers the flexibility to choose the most

suitable option for each garment or product. Improved Appearance: Fusible interlining improves the overall look of the garment by

preventing it from sagging or losing shape, giving it a crisp,

professional finish. Cost-Effective: The application of fusible interlining can reduce the need for

more expensive construction methods or additional layers of fabric,

making it a cost-effective choice for manufacturers.

ConclusionFusible interlining is a versatile and essential material in garment manufacturing,

offering support, shape, and durability to various types of

fabrics. Whether used in shirts, coats, or skirts, fusible

interlining provides a simple and efficient way to enhance the

structure and longevity of garments. At Shanghai Uneed Textile Co., Ltd., we offer high-quality fusible interlining in a variety of types,

weights, and finishes to meet the needs of different industries.

Our products are designed to ensure easy application, durability,

and superior performance, making them the perfect choice for your

garment production needs |