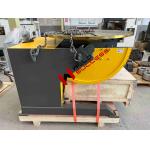

2000kg Hydraulic Lifting 3 Axis Positioner With Electric Control System

|

|

2-ton hydraulic welding positioner is a specialized piece of equipment used in welding operations to position and rotate workpieces. It is designed to handle workpieces weighing up to 2 ton, providing stability and controlled movement during welding processes. Here are some key features and characteristics of a 2-ton hydraulic welding positioner: Load Capacity: The positioner is capable of supporting and rotating workpieces with a maximum weight capacity of 2 ton. This makes it suitable for handling smaller and medium-sized workpieces in welding applications. Rotation Control: The hydraulic welding positioner includes a hydraulic system that allows operators to control the rotation speed and direction. This enables precise control over the positioning and movement of the workpiece during welding operations. Adjustable Positioning: The positioner often features adjustable positioning options, such as tilting, rotating, and height adjustment. These adjustments allow for optimal positioning of the workpiece, ensuring easy access to weld joints and improving welding efficiency. Hydraulic Power: The hydraulic system of the positioner provides smooth and controlled movement, allowing for precise alignment and rotation of the workpiece. It offers stability and eliminates the need for manual handling, reducing operator fatigue and enhancing safety. Sturdy Construction: The positioner is typically made of robust materials to ensure durability and stability during operation. It is designed to withstand the weight of the workpiece and provide a secure platform for welding processes. The 2-ton hydraulic welding positioner is commonly used in various industries, including fabrication shops, automotive manufacturing, and small-scale welding operations. It assists in achieving accurate and efficient welding by providing controlled positioning and rotation of workpieces. |

| Product Tags: 2000kg 3 Axis Positioner Hydraulic Lifting 3 Axis Positioner Electric Control System 3 Axis Positioner |

|

2 Ton Pipe Welding Positioners For Pipe Turning Welding |

|

Manual Bolt Height Adjust 1-Ton Welding Positioner |

|

600kg Pipe Welding Positioners Robust Construction |

|

2 Ton Pipe Welding Positioners For Pipe Turning Welding |

|

2T Rotory And Tiltling Welding Positioner With Foot Pedal And Hand Box |

|

YHB-30-3000kg Hydraulic Lifting 3 Axis Positioner With Electric Control System |