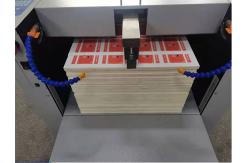

PRY-A5575 Automatic Sheet Fed Thin Paper Die Cutting Machine with Stripping

|

Detailed Product Description

|

PRY-A5575 Automatic Die Cutting Machine with Stripping Features Roller die cutting machine is to cut the paper with the mould.It

can be applied to normal paper,coated paper and cardboard,(the

following paper cannot be processed:composite paper(covered with

polypropylene)or plastic film).Speed can reach 6000 cycles per

hour.It can remove the waste automatically,easy to operate and save

time with the efficient work. 1.Operation Console Both setup and control can be done though the intuitive touch screen.After setting upper and lower die,the system can be set up by simply inputting sheet size and product size.The graphical illustrations on the screen are simple and easy to understand. 2.Feed Section Vacuum belt feeding enables superior feeding with easy setup and operation.An ultrasonic sensor is used for double feed detection on a wide range of substrates. 3.Transport Section Sheets are registered by vacuum belt and position is firmly secured with gripper rollers for high quality finish. Servo motor driven gripper rollers ensure the die cut position without effecting processing speed. 4.Die Cutting Rigid magnetic upper roller and solid lower anvil roller ensure high quality die cutting. Uniquely designed die cutting section enables easy and quick die setting.Both 0.6mm and 0.8mm/0.0236’’ and 0.0315’’ thickness of flexible die plates can be used. 5.Separator The separator removes the waste from the finished product and delivers it to the waste bin. Air cylinder driven separator pins and sir jets can be used depending on size of the waste. 6.Delivery Section Finished products are delivered on the motorized conveyor.Intermittent conveyor movement maximizes the continuous operation in a small space.Gap can be adjusted depending on the size of the product for easy handling. 7.Multi-functional system die cutting,kiss cutting creasing,repeat cutting. 8.Rotary die cutting machine(Max.400x550 mm)-rotary die-cutter designed to meet the growing demand. 9.Flexible substrate-die cut,crease,perforation,silt,hole punch and round corner in various substrates up to 0.5mm(only for die cutting)thickness for digital and offset printed sheets. 10.One pass processing-feeding,die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour. 11.Save the cost of making die-uniquely designed servo motor controlled ”Repeat Register” feature allows multiple-up applications from single-up die to minimize die cost.Simple and easy operation-reduces costly labor steps and increases productivity. Use and Scope of Use *The integrated PRY-A5575 rotary die cutting machine is a suitable

equipment for different production.It is suitable for small batch

and repeated production.It use flexible mould and easy to replace. *Through the flat-type paper feeder and positioning table,the paper enters the die-cutting section,and the positioning accuracy of the paper-feeding direction can reach ±0.1mm. *Automatic paper lifting,automatic paper feeding,double sheet detection,chasing mark alignment die cutting,automatic deviation correction,automatic waste discharge and other functions. *The separator section can be directed to blow away waste,and adjustment does not require tools. *The separator section and collection section can be pushed away as a whole,providing maximum convenience for changing the mould. *The wheel of separator section is electrical control,timing up and down,the final product will be output to the receiving table regularly. *Automatic paper lifting,automatic paper feeding,double sheet detection,chasing mark alignment die cutting, automatic deviation correction,automatic waste discharge and other functions. *Mainly suitable for stickers,tags,wine labels,playing cards,small boxes and so on.The processing materials are suitable for plain paper,coated paper,cardboard,PE film,and so on. *This section describes the sheet flow from the feed unit through the die cutter and the separator.The separator separates the cut product from the sheet. Technical Parameters

Configuration 1.Smart Touch ScreenHuman-machine interface,intelligent touch screen simple and

beautiful appearance, complete internal functions,simple and clear

operation. 2.Multi-Function Die Cutting The machine have multifunction:die cutting,creasing,kissing and

repeat cutting,sutitable for the size of matrial within B2

size(including B2 size). 3.Feed Section Automatic paper lifting,automatic paper feeding,double sheet

detection,the machine through the flat-type paper feeder and

postioning table,the paper enters the die-cutting section,and the

postioning accuracy of the paper feeding direction can reach 0.1mm. 4.Receiving Part Lower suction to stabilize the paper output,finished products will

be regular output to the receiving table. 5.Flexible Knife Plate Flexible knife plate,diversified styles,easy to change. 6.High Speed and Precision It can reach speeds of up to 6,000 pcs per hour. Applicable All Kinds of Stickers Hanging Tags Card Paper Box Wine Label Q1.Are you a manufacturer or a trading company? A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou,Zhejiang Province. Q2.What is the machine warranty? A:One year.After the warranty,we still provide technical support to

buyer at low cost. Q3.What is the production time while placing order? A:Normally about 10-20 days. Q4.What is the delivery time? A:15-30days after deposit. Q5.Can your company handle shipping for customers? A:Yes,just give us destination sea port or container yard. Q6.Does the packing strong? A:Yes.Adopts moisture-proof and shock-proof packaging which is

suitable for long-distance road transportation and various types of

weather conditions.A full set of maintenance and operation manuals is included. Q7.How about the machine installation and training? A:1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for

installation and training.You shall pay the round trip air fare and accommodations,plus each

technician charges USD100/per day. Q8.Do you have machines in stock? A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you. Q9.How can you assure the machines’ quality? A:Each machine will be test running at least 24 hours before

delivery to assure the quality. And during the warranty,we will give spare parts for free if

machine has any problem. Q10.Do you inspect machines or test running before packing? A:Of course we do.We have QC department to debug the machine before

packing. If you want to use specific material to do the test running,you

need to pay for the cost of the material. Q11.What’s the payment term? A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight. Q12.Do you accept factory visiting? A:Warmly welcome for your visiting. Q13.How many years are you in printing field? A:The Shanghai company since in 2008,the factory is more than

25years. Q14.How many clients do you have? A:We have sold our machines to about 60 countries.We have agents in South Africa,Morocco and Italy. |

||||||||||||||||||||||||||||

| Product Tags: Automatic Sheet Fed Paper Die Cutter Paper Die Cutting Machine 550mm 100sheets/min Paper Die Cutting Machine | ||||||||||||||||||||||||||||

Related Products

|

Billboard Envelope Hydraulic Punching Machine 200mm Slide Stroke |

|

Hydraulic Stable Beer Label Punching Machine 3kw 12000 Sheets/Min |

|

30s Replace Cutting Die 30KN Sakura Punching Machine |

|

LPM-500 Hydraulic 50KN Beer Labels Paper Punching Machine |

|

LPM-150 1.5kw Cutting Stroke 200mm Paper Die Cutting Machine |

|

PRY-H920 Automatic Rotary Die-cutting Machine |

Email to this supplier