GL Series Water Base Glue Thermal PET Film Laminating Machine Dual Function

|

Detailed Product Description

|

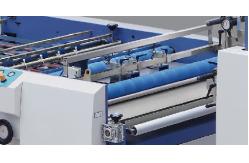

GL-1080 Film Laminating Machine Features Feeder *Sheets pre-stacker provides a continuous feed without a stop *Servo-controlled feeder head,synchronizing with the host speed,replenishes sheets *Sheets gap sensor for self-protection *Overlap regulator & Side-lay regulator Powder Remover *Electric-heated powder remover improves film-sheet fastness and laminating effect Laminator *Electromagnetic-heated,chrome laminating roller and hydraulic-pump driven rubber roller *High-precision glue applying roller and glue scraper *Φ800 large diameter steel roller and the electromagnetic heater dry glue instantaneously *Pre-coated film mounted on a quick-change,micro-adjustable air-shaft *Air-shaft ensures precise film release tension and speed *Film roll slitting and perforating mechanisms *Film rewinders for pre-coated or uncoated left film Sheeter *Anti-curl assembly de-curls thin sheets after thermal lamination *Steer wheels exert negative force on one side to help with sheeting *Rotatory perforating mechanism prepares the web for subsequent sheeting *High-speed mechanical sheeting system driven by steady pneumatic assembly Stacker *Corrugated delivery system flattens and delivers sheets *Slow-down drop wheels *Side joggers and back-stop stack sheets in order *Non-stop automatic stacker with a sheets counter Others *Suitable for both pre-coated film lamination and uncoated film lamination *Feed,overlap and side-lay adjustment,powder removal,laminating,drying,sheeting and stacking are finished in one pass Optional *Double lamination unit improves laminated film fastness *Embossing system improves sheets exquisiteness to maximize the products value *UV film reinforcement system avoids film peeling and blisters *Chain knife sheeting system facilitates PET and PVC film sheeting *Advanced hot-knife sheeting system,combining hot-knife and the pneumatic sheeting system,features accurate and stable sheeting,no excess film,and high running speed *Code printing system that features a high-precision sprayer and precise printing is suitable for QR code printing *Plastic removal assembly contributes to plastic film recycling and reusing Technical Parameters

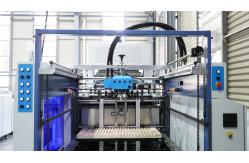

Configuration Automatic FeederEquipped with pre-feeder and electric paper feeding system ensures

paper continuity Mechanical Side Lay RegisterMake sure the sides of paper are neat Powder RemoverHeating roller with scraper effectively remove the powder which

enhance the brightness and adhension of the laminating paper Electromagnetic HeaterElectromagnetic heater heat up the surface of heating roller

directly,Fast heating speed and energy saving Water-Base Glue & Thermal Film Dual Function LaminatorThe machine can do thermal film or water-base film according to

customer’s request Coated Glue UnitCoated steel roller is chrome-plated and high-precision special

treatment,Frequency conversion drive eliminate the phenomenon of

glue being thrown out and ensure uniform coating.Using big drying

roller,the dia of roller is 900mm Anti-Curvature DevicePrevent thin paper from curling after lamination Mechanical Separation SystemEquipped with double rotary knife to help separate the paper,High

speed and fast response High Speed Automatic StackerThe pneumatic stacker receives the paper,keeping them in

order,while rapidly counting every sheet Double lamination unit (Optional) Embossing System(Optional) UV film reinforcement system (Optional) Chain knife sheeting system(Optional) Advanced hot-knife sheeting system (Optional) Code printing system(Optional) Plastic removal assembly(Optional) Q1.Are you a manufacturer or a trading company? A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou,Zhejiang Province. Q2.What is the machine warranty? A:One year.After the warranty,we still provide technical support to

buyer at low cost. Q3.What is the production time while placing order? A:Normally about 10-20 days. Q4.What is the delivery time? A:15-30days after deposit. Q5.Can your company handle shipping for customers? A:Yes,just give us destination sea port or container yard. Q6.Does the packing strong? A:Yes.Adopts moisture-proof and shock-proof packaging which is

suitable for long-distance road transportation and various types of

weather conditions.A full set of maintenance and operation manuals is included. Q7.How about the machine installation and training? A:1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for

installation and training. You shall pay the round trip air fare and accommodations,plus each

technician charges USD100/per day. Q8.Do you have machines in stock? A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you. Q9.How can you assure the machines’ quality? A:Each machine will be test running at least 24 hours before

delivery to assure the quality. And during the warranty,we will give spare parts for free if

machine has any problem. Q10.Do you inspect machines or test running before packing? A:Of course we do.We have QC department to debug the machine before

packing. If you want to use specific material to do the test running,you

need to pay for the cost of the material. Q11.What’s the payment term? A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight. Q12.Do you accept factory visiting? A:Warmly welcome for your visiting. Q13.How many years are you in printing field? A:The Shanghai company since in 2008,the factory is more than

25years. Q14.How many clients do you have? A:We have sold our machines to about 60 countries.We have agents in South Africa,Morocco and Italy. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Thermal PET Film Laminating Machine Water Base Glue Film Laminator Dual Function Film Laminating Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

PRY-ER Roll to Roll Fully Automatic Vertical Film Laminating Machine |

|

PRY-V480 Mini Heated Rubber Roll Manual Film Laminator |

|

PRY-1650C BOPP PET Nylon CPP CPE Aluminum Foil Automatic Film Laminating Machine |

|

PRY-390A Digital Semi Automatic Economic Film Laminating Machine |

|

YFMB-1400 Semi Automatic Split Pre-Coated Thermal OPP PET PVC Film Laminating Machine |

|

FM-1100 Multifunctional Automatic Vertical Film Laminating Machine With Round Knife |

Email to this supplier