Plastic OPP PET PVC Metallic Thermal Film Laminating Embossing Machine Double Sides

|

Detailed Product Description

|

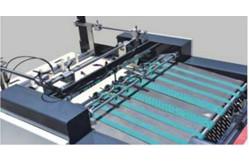

YFMA-760 Automatic Laminating Machine Features YFMA-760 fully automatic laminating machine as a professional

equipment used for plastic film laminating on the surface of paper

printer matter. * Thermal laminating (Pre-coated /thermal film) * Film:OPP,PET,PVC,METALLIC,etc. Technical Parameters

Configuration Automatic Paper Feeding Unit The paper feeder is an important part of the coating machine.The function of the paper feeder is to automatically,accurately,steadily and periodically separate the sheets one by one,and continuously send them to the regular positioning parts. The paper feeding method of this machine is continuous paper feeding,which has the advantages of high automation,compact structure,good performance,convenient operation,accurate paper feeding and high precision.The main components of the paper feeder are paper feeding bridge,paper feeding head,paper stacking table,lifting system and transmission system. (1)Adopt oil-free vacuum air pump suction system; (2)High-speed offset printing feeder(12,000 sheets/hour)ensures high speed and stable operation; (3)Stepless frequency conversion speed regulation paper feeding; Suction Device(4)The paper feeding table of the production line is positioned and conveyed by vacuum suction to ensure smooth,tidy and stable conveying; (5)The upper and lower limit protection devices of the feeding table;manual rapid lifting; (6)The paper feeding table automatically replenishes the paper feeding system; (7)Attached double sheet controller:double or multiple sheet feeding detection and shutdown system:use the induction of the safety voltage. Equipped with a turbofan suction motor and a servo-synchronized paper feeding belt to ensure that the paper is stably fed to the front gauge device. Front Lay The servo motor controls the front lay and the feeder to synchronize,and the cam mechanism precisely controls to ensure the value of the edge covering. Side Lay The servo-controlled side lay is synchronized with the feeder,and the cam mechanism precisely controls the side pull to ensure that the side edges of the paper are aligned. Electromagnetic Heater Unit It adopts the international advanced electromagnetic heating control technology, which has the characteristics of fast heating speed and easy temperature control. Loading and Unloading Unit Air shaft equiped with clutch device can adjust film release extension and speed. Man-Machine Interaction System The color touch screen operation interface can quickly and conveniently input and view the parameters of the machine operation. Anti-Warping Device Prevent the paper from warping due to film shrinkage,ensure the paper is flat and has the characteristics of easy adjustment and no shaking. Automatic Delivery System The automatic paper delivery system is equipped with a fan-cooled paper pressing structure,which can perfectly deliver the paper under the high speed operation of the machine,ensuring that the paper is delivered neatly. (1)The belt has low-noise delivery,and the upper and lower rails are designed to ensure smooth delivery; (2)The thin paper coating is prone to curling, and the vacuum suction paper vstabilizer device keeps the paper stable; (3)The delivery table can be raised and lowered manually; (4)The upper and lower limit protection devices of the delivery

table; Pneumatic Slitting System(5)The automatic lowering device of the delivery table,and the delivery limit paper stop and alarm system; (6)Automatic coating paper cumulative count. Equipped with flying knife,pneumatic punching device,photoelectric detection,need to adjust the cutting position according to the size of the paper,high-speed automatic cutting. Double Sided Lamination Unit(Optional Unit) To solve the problem of two times lamination,making more profits

for users. Chain Cutter(Optional Unit) Chain cutter system applying pet,pvc film and etc. having the feature of accurate separation without film margin. Second Lamination Unit(Optional Unit) The second lamination enhances the bond strength of the lamination. Embossing Unit(Optional Unit) Embossing process makes paper good-looking and valuable. Applications Widely applicable for laminating in packaging,paper

box,books,magazines,calendars,carton, handbags,gift box, wine

packaging paper improving the printing matter grades,and achieve

the purpose of dust-proof,water-proof, oil proof.It’s the best

choice for printing and laminating enterprises of all scales. Q1.Are you a manufacturer or a trading company? A:Our shanghai office is mainly doing export.We have our own factory in Wenzhou,Zhejiang Province. Q2.What is the machine warranty? A:One year.After the warranty,we still provide technical support to

buyer at low cost. Q3.What is the production time while placing order? A:Normally about 10-20 days. Q4.What is the delivery time? A:15-30days after deposit. Q5.Can your company handle shipping for customers? A:Yes,just give us destination sea port or container yard. Q6.Does the packing strong? A:Yes.Adopts moisture-proof and shock-proof packaging which is

suitable for long-distance road transportation and various types of

weather conditions.A full set of maintenance and operation manuals is included. Q7.How about the machine installation and training? A:1)We provide training in our factory for free; 2)We can send technicians (engineers) to your factory for

installation and training. You shall pay the round trip air fare and accommodations,plus each

technician charges USD100/per day. Q8.Do you have machines in stock? A:For standard model,we have a large quantity in stock.For special model,we need 20-30 days to produce it for you. Q9.How can you assure the machines’ quality? A:Each machine will be test running at least 24 hours before

delivery to assure the quality. And during the warranty,we will give spare parts for free if

machine has any problem. Q10.Do you inspect machines or test running before packing? A:Of course we do.We have QC department to debug the machine before

packing. If you want to use specific material to do the test running,you

need to pay for the cost of the material. Q11.What’s the payment term? A:T/T 30% in advance,the balance shall be paid before delivery.We also accept payment by West Union or L/C at sight. Q12.Do you accept factory visiting? A:Warmly welcome for your visiting. Q13.How many years are you in printing field? A:The Shanghai company since in 2008,the factory is more than

25years. Q14.How many clients do you have? A:We have sold our machines to about 60 countries.We have agents in South Africa,Morocco and Italy. |

||||||||||||||||||||||||||||||

| Product Tags: PVC Metallic Thermal Film Laminating Machine OPP Film Embossing Laminating Machine Double Sides Plastic Film Embossing Machine | ||||||||||||||||||||||||||||||

Related Products

|

PRY-ER Roll to Roll Fully Automatic Vertical Film Laminating Machine |

|

PRY-V480 Mini Heated Rubber Roll Manual Film Laminator |

|

PRY-1650C BOPP PET Nylon CPP CPE Aluminum Foil Automatic Film Laminating Machine |

|

PRY-390A Digital Semi Automatic Economic Film Laminating Machine |

|

YFMB-1400 Semi Automatic Split Pre-Coated Thermal OPP PET PVC Film Laminating Machine |

|

FM-1100 Multifunctional Automatic Vertical Film Laminating Machine With Round Knife |

Email to this supplier