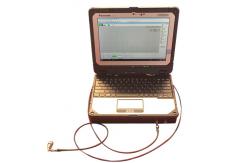

HFD-SW30 Automotive Welding Spots Ultrasonic Testing Integrated System

|

HFD-SW30 Automotive Welding Spots Ultrasonic Testing Integrated SystemThe ultrasonic testing system HFD-SW30 for car welding points is an integrated system independently developed by HUATEC Group. The core components of the system adopt original imported brands, laying the foundation for the stability and consistency of the subsequent system; The data collection and analysis docking software is developed by our own company, relying on the data background of senior engineers engaged in welding processes in the automotive industry. The system can interface with any management software of the company to achieve cloud data management and analysis. The on-site inspection data can be presented on the factory's digital screen, displaying the welding point detection status, laying the foundation for the realization of an information factory. Product Features Automatic evaluation function and detection result data processing function. The testing system customizes testing plans and plans based on standards, automatically evaluates the quality of solder joints, and generates testing standards and reports. Centralized data management is optional, with on-site testing data presented on the factory's digital screen, displaying the status of solder joint testing, laying the groundwork for the implementation of information technology plants (optional). Including: Classify, organize, store, and manage detection data, store and organize these data, achieve connections between data, improve storage space utilization, facilitate access, and improve access efficiency. Implement basic operations on data, such as querying, inserting, deleting, and modifying. Unified management and control to ensure data security, integrity, and concurrent use by multiple users. Data input, conversion, storage, recovery functions, restructuring functions, performance monitoring, analysis functions, etc. The detection system is convenient for on-site operation and portability, and is built-in in the military industrial three defense laptop, providing better protection for the ultrasonic transmitter. Characteristics

Technical parameters1. Storage temperature: -51+ 71 ° C 2. Working temperature: -29+ 63 ° C 3. External dimensions: 25 × one hundred and eighty-three × 85 mm 4. Weight: approximately 1.98kg 5. Protection level: meets the US military standard MIL-810G standard, and the waterproof and dustproof levels reach IP65 standard Seismic/impact resistant/wide temperature resistant, passing 120cm drop test, keyboard waterproof 6. Impact resistance: maximum 0.15 grams/11 milliseconds, in accordance with IEC60068-2-27 standard 7. Vibration resistance: 5-150 Hz, maximum 2 grams, 1 octave per minute, in accordance with IEC60068-2-6Fc standard 8. Probe interface: LEMO 00 or Microdot 9. Device input/output interface: expansion bus port 10. Power interface: power adapter 11. USD: 3.0 12. Working power supply Working voltage: 5V DC, provided through the built-in interface of the computer 13. Encoder power supply: external power supply 100-230 volts; AC power; Maximum power 5W 14. Power consumption: maximum power consumption 2.5W 15. Ultrasonic pulse type: sharp wave pulse 16. Repetitive frequency PRF: maximum value 1000Hz, 3 modes (depending on calibration range), continuous adjustment range 8-1000Hz, discontinuous pulse sequence, excitation voltage: maximum 400V 17. Charging capacitor: 1 nF, 220 pF 18. Starting wave rising edge time:<15nS 19. Ni: 50 ohms, 1000 ohms 20. Probe mode (TR): on/off, penetration 21. Set and evaluate calibration range: minimum 0-2.5mm, 0-0.1 inches (in steel); Maximum 0 to 9700mm, 0 to 381 inches (in steel) 22. Sound speed range: 500~15000 m/s, 0.02~0.59 "/ μ S; Has a complete and editable material list 23. Pulse offset: -10~1500 mm; - 0.39~50 "(in steel) 24. Probe delay: 0~100 μ S 25. Frequency range: 0.5~20 MHz (-3 dB); 4 filters 26. Repetition frequency range: 1-1000Hz; Automatically or manually adjustable 27. Gain: 110 dB, adjustable step 0.5/1/2/6 dB 28. Working mode: pulse reflection type, double crystal, with the latter penetrating 29. Detection: Full wave, positive half wave, negative half wave, RF radio frequency (maximum 150 mm/5.9 "in steel) 30. Suppression: 0-90% linear 31. DAC/TCG: DAC has a maximum of 16 data points (reference reflector), a dynamic range of 37 dB, and a maximum slope of 6 dB/ μ S; 3 adjustable curves; Convertible to TCG mode (time gain correction) (horizontal recording threshold); Meet domestic and international testing standards 32. DGS: DGS records the effective equivalent reflectance size curve of all probes with DGS function; Can be set as DAC or TCG; The evaluation method can be displayed as a dB value related to the curve, equivalent diameter, or evaluation level (JIS); Sound velocity attenuation and transmission correction; Reference reflectors can be selected as flat bottomed holes, horizontal holes, or large flat bottoms 33. Monitoring gate: 2 independent monitoring gates, with gate width exceeding the maximum calibration range; Evaluation is based on A-scan; Gate alarm: closed, synchronous, asynchronous; Logic: and/or acoustic alarm 34. Distance measurement: It can measure the distance between the wave side or peak of the echo in an independent gate (A gate or B gate) and the zero point; Or measure the distance difference between the echoes between the gates: Gate B - Gate A 35. Measurement resolution: The maximum sound path/degree over time is 12.6mm: 0.01mm; Or 0.2% full screen width 36. Vertical resolution: 0.5% full screen height or 0.2dB 37. A-scan digitization: 1024 × 1024 pixels 38. Display freezing: static A-scan freezing, dynamic A-scan freezing (peak, real-time dynamic signal), with an average freezing of 2-3 cycles of ultrasound pulses 39. Echo comparison: simultaneously displaying the current dynamic signal and the accessed A-scan signal 40. Language: German, English, French, Spanish, Chinese, Japanese 41. Unit: millimeters, inches, subtle 42. Data storage: The database can save and manage instrument settings, testing tasks, and testing results; Including A-scan, DAC, and text annotation; And import Microsoft Excel spreadsheet; The storage capacity is limited by the size of the hard drive. |

||||||||||||||||

| Product Tags: Automotive Welding Spots Testing Integrated System Ultrasonic Testing Integrated System Automotive Welding Spots Ultrasonic System |

|

Handheld Digital Touch Screen Xrf Alloy Analyzer |

|

High Voltage Pinhole Detector Portable Holiday Detector Nondestructive Flaw Detection |

|

High Radiation 250kv XXQ-2505 Portable X Ray Flaw Detector |

|

Intelligent Digital Display Handheld Portable Alloy Analyzer HXRF-120DP |

|

Underground Pipe Locator And Porosity Holiday Detector |

|

Intelligence Pulsed High Voltage Pinhole Detector Protecting Coating Quality |