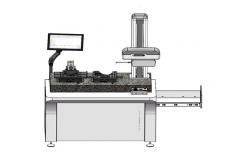

SRT-680G Roughness and Contour Tester

Measurement Principle

● Cartesian coordinates, stylus contacts.

● High precision air floating guide rail –As the measuring datum of

X coordinate to guarantee the linear moving accuracy in X

direction.

● High precision digital sensor – to get signal of Z coordinate for

measuring the profile of various precise mechanical piece part.

● Computer and windows-based measuring program to process the

measuring data, easy for printing and filing

Main Function

Dimension:Contains the horizontal distance, vertical distance,

linear distance, radius and diameter

Angle: Horizontal Angle, vertical angle, cross angle

Position tolerance: contains the parallelism and perpendicularity

Form tolerance: contains the straightness, crown, circular arc

profile

Auxiliary generation: contains the auxiliary point, auxiliary line,

auxiliary circle

Roughness:Ra,Rq,Rz(Ry),Rz(DIN),R3z,Rz(jis),Rp,Rv,Rt,Rsk,Rsm,Rc

,Rpm,RkuRdq,Roc,Mr1,Mr2,Rpk,Rvk,Rk,Rdc,A1,A2,R,Rx,AR,Rcp,Rmax,Rz-ISO

etc.

Waviness:wt,wa,wp,wv,wq,wc,wku,wsk,w,wx,wz,wsm,wdc,wte,wmr,Aw,c(wmr)wmr(c),wdq

etc.

Original contour Pt Pa Pp Pv Pq Pc Pku Psk Pdq/p△q Psm Pdc Pmr(c)

Pz Pmr C(pmr) etc.

Main Parameters | Item | Parameter | Resolution | Measurement range Measurement Accuracy | X axis | 200mm | 0.1μm | | Straightness | 0.6μm /100mm | -------- | | Z1(range)Sensor | 40mm(Roughness range synchronization) | 0.05μm | | Z Height | 550mm | colume | | Min. inner hole | 30mm (A smaller inner diameter can be measured by using a smaller

measuring needle) | ---------- | | Linear accuracy | ≤±(1+I0.12HI)μm | - ------ | | Arc | ≤(1.2+R/8) | 2mm<R<10mm standard ball, The included Angle of the sampling

arc:120° | Angle | ≤±1′ | 60°,90° angle block, The sampling length of the corner:5mm | | Roughness | Residual value noise | ≤0.005μm | λc:0.08mm,testing speed 0.1mm/s, measure flat crystals | | Z1(range)Sensor | Effective range±3mm | The roughness of the curved surface can be measured | | Roughness measurement repeatability | 1δ≤2nm | Ra 0.35-0.5μm Square wave calibration block | | Indication error | ±5% | National standard | | Indicative stability | ≤±7% | National standard | | Repeatability measurement | ±3% | National standard | | Resolution | 0.1μm | ---------- | | Sensor | Type | Digital grating sensor | ----------- | | Resolution | 0.05μm | ------- | | Assessment length | λc×3,4,5,6,7 | --------- | | Cut-off wavelength | 0.025,0.08,0.25,0.8,2.5,8mm | ---------- | | Climbing Ability | 77°(Upside),88°(Downside) | ------- | | Meas. Speed | 0.02mm to 4.0mm/s | ---------- | | Meas. Mode | Sensor moving | -------- | | XZ1Z | Three-axis electric control | It can be controlled by the software controller | | Power | AC 220V±10% 50Hz | ------- | | Environmental conditions | (RH):<85% 20℃± 2℃,2℃/h ,RMS≤50Hz 2.5μm/s ,RMS>50Hz 5.0μm/s |

Main configuration

Software interface

Equipment size

| (Product) | (Packing) | (Wt.kg) | (CBM m³) | | Lx | Ly | Lz | Wt(kg) | Lx | Ly | Lz | Wt(kg) | | 1400 | 725 | 1740 | 270 | 960 | 960 | 1950 | 50 | 300 | 0.88 |

Usage requirement

Power: AC 220V±10% 50Hz

Environment requirement:(T):10~30℃,(RH):<85%,No obvious

vibration,Independent grounding

Testing reference photos

|