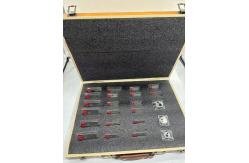

ASTM SE 1025 plate penetrameters

ASTM SE 1025 Plate Penetrameters are normally used to conform with

the AmericanInspection Standards.

They are rectanqular plates, 2% in thickness of the specimenand of

material radiographically similar to the specimen.

Each plate has three holesdrilled equal in diameter to 1X, 2X, and

4X the plate penetrameter thickness.

Theminimum thickness of Plate type penetrameter is 0.010". For

Penetrameters greaterthan 0.180",

these are supplied in disc form, the outside diameter is 4X, with 2

holes1X & 2X the thickness ofthe Penetrameter.

The chart below gives Plate PenetrameterIdentification and

thickness and a guide as to which penetrameter to use for

eachmaterial thickness.

| :mm |

| No. | Thickness | Aperture T | Aperture 2T | Aperture 4T |

| Range | Measured | Range | Measured | Range | Measured | Range | Measured |

| 5 | 0.1143-0.1397 | 0.1395 | 0.241-0.267 | 0.261 | 0.495-0.521 | 0.519 | 1.003-1.029 | 1.023 |

| 7 | 0.165-0.191 | 0.189 | 0.241-0.267 | 0.263 | 0.495-0.521 | 0.519 | 1.003-1.029 | 1.025 |

| 10 | 0.241-0.267 | 0.247 | 0.241-0.267 | 0.264 | 0.495-0.521 | 0.519 | 1.003-1.029 | 1.017 |

| 12 | 0.275-0.335 | 0.311 | 0.275-0.335 | 0.329 | 0.608-0.667 | 0.654 | 1.238-1.302 | 1.298 |

| 15 | 0.349-0.413 | 0.392 | 0.349-0.413 | 0.368 | 0.730-0.794 | 0.762 | 1.492-1.556 | 1.522 |

| 17 | 0.400-0.464 | 0.406 | 0.400-0.464 | 0.411 | 0.857-0.921 | 0.911 | 1.746-1.810 | 1.795 |

| 20 | 0.476-0.540 | 0.484 | 0.476-0.540 | 0.505 | 0.984-1.048 | 1.019 | 2.000-2.064 | 2.018 |

| 25 | 0.571-0.699 | 0.653 | 0.571-0.699 | 0.646 | 1.206-1.334 | 1.288 | 2.476-2.604 | 2.498 |

| 30 | 0.698-0.826 | 0.769 | 0.698-0.826 | 0.721 | 1.460-1.558 | 1.514 | 2.984-3.112 | 3.039 |

| 35 | 0.825-0.953 | 0.887 | 0.825-0.953 | 0.907 | 1.714-1.842 | 1.766 | 3.492-3.620 | 3.577 |

| 40 | 0.952-1.080 | 0.972 | 0.952-1.080 | 1.019 | 1.968-2.096 | 1.987 | 4.000-4.128 | 4.118 |

| 45 | 1.079-1.207 | 1.201 | 1.079-1.207 | 1.201 | 2.222-2.350 | 2.31 | 4.508-4.626 | 4.619 |

| 50 | 1.206-1.334 | 1.311 | 1.206-1.334 | 1.314 | 2.476-2.604 | 2.535 | 5.016-5.144 | 5.106 |

| 60 | 1.397-1.651 | 1.527 | 1.397-1.651 | 1.535 | 2.921-3.175 | 3.014 | 5.969-6.223 | 6.055 |

| 70 | 1.714-1.842 | 1.832 | 1.714-1.842 | 1.832 | 3.492-3.620 | 3.595 | 7.048-7.176 | 7.110 |

| 80 | 1.905-2.159 | 2.002 | 1.905-2.159 | 1.952 | 3.937-4.191 | 4.061 | 8.001-8.255 | 8.028 |

| 100 | 2.413-2.667 | 2.653 | 2.413-2.667 | 2.637 | 4.953-5.207 | 5.197 | 10.033-10.287 | 10.265 |

| 120 | 2.921-3.175 | 3.011 | 2.921-3.175 | 3.012 | 5.969-6.223 | 6.123 | 12.065-12.319 | 12.301 |

| 140 | 3.429-3.683 | 3.523 | 3.429-3.683 | 3.612 | 6.985-7.239 | 7.156 | 14.097-14.351 | 14.251 |

| 160 | 3.937-4.191 | 4.015 | 3.937-4.191 | 4.101 | 8.001-8.255 | 8.155 | 16.129-16.383 | 16.295 |

| 200 | 4.826-5.334 | 5.135 | 4.826-5.334 | 5.012 | 9.906-10.414 | 10.125 | | |

| | The test results meet the requirements of ASTM E1025 | |