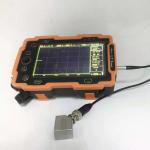

Auto Calibration Function Portable Ultrasonic Flaw Detector SD Card Touch Screen

|

|

Auto Calibration Function Portable Ultrasonic Flaw Detector SD Card Touch Screen

Features ●High-precision quantification and positioning to meet the requirements of near and far distance detection ●The near-field blind zone is small, can meet the detecting requirements for small-diameter and thin-walled pipe. ●Auto calibration function:one-button auto calibration,easy to operate, automatic test probe “P Delay”,”K value”,”X value” and the velocity ●Automatic display the defect echo position(Depth:d, Horizontal:p,Distance:s, Amplitude,dB,ф ) ●Switch three scales freely(Depth:d, Horizontal:p,Distance:s) ●Auto gain, peak envelope, peak memory functions, which can improve the detection efficiency. ●Automatically record the flaw detection process and dynamic playback ●φ value calculation:Forging flaw detection by straight probe, can find the highest wave to conversion φ value automatically ●500 independent channels(can be expandable), which can input and store the detection standards of any industries freely, do not need to carry the standard blocks for on-site inspection. ●Store, playback 500 A-scan waves and data freely ● The DAC, AVG, and TCG curves (depth compensation) are automatically generated and can be segmented. The sampling points are unrestricted and can be corrected and compensated. ●14 built-in inspection standards ●Free to enter any industry standards ●Pulse width and strength can adjustable ●B scan and B color scan function; ●Can communicate with the computer, and export WORD. File, also the detection report ●IP65 ABS plastic case, sturdy and durable,water-proof and dust-proof, and excellent anti-interference ability ●Use (wireless) communication software to analyze data print reports, etc; ●260,000-color true color screen, is suitable for working environment under strong light or low light ●High performance lithium battery, can work continuously for 8-10 hours ●Real-time clock recording: real-time flaw detection date, time tracking record, and storage ●Power-down protection, storage data can not lost ●Flaw detection parameters can be automatically tested or preset ●Digital reject, does not affect gain and linearity ●Gain compensation: Db attenuation can be corrected for surface roughness, curved surfaces, long-range flaw detection of thick work-pieces, etc. ●Can operate the flaw detector by software at the PC, achieving the goal of computer-controlled flaw detector to detecting

Technical Specification

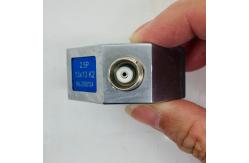

Standard Configuration

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Touch Screen Ultrasonic Flaw Detector SD Card Ultrasonic Flaw Detector Portable Ultrasonic Flaw Detector | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Light Weight Small Volume Mini 1mm Ut Flaw Detector |

|

Portable 64 Ch Hpa-500 Phased Array Ultrasonic Flaw Detector Phased Array Flaw Detector |

|

Mini Portable Industrial Non Destructive Ut Flaw Detector |

|

Auto Calibration Digital 7" Portable Ultrasonic Flaw Detector |

|

Carbon Steel Ultrasonic Asme 19mm Calibration Test Block |

|

1/2-T-R High Resolution TFT Screen (640×480) Railway Digital Ultrasonic Flaw Detector |