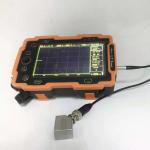

Fast Charging Flaw Detector Ultrasonic With Lithium Ion Battery

|

|

Ultrasonic Depth Tester for Induction Hardened Layer TG-8000

Background:

Surface hardening treatment can improve the wear resistance and fatigue strength of components subjected to dynamic stress. These characteristics are mainly determined by the surface hardness, hardened depth, and depth profile of residual stress. The depth of the hardened layer is an important quality indicator in the surface hardening treatment process. Currently, the quality of the hardening process can only be ensured through random testing methods. This method not only damages components, wastes time, but also has a high cost.

Cong

Solution: Our company uses a fast, non-destructive ultrasonic method to measure the depth of hardened layers. This method can reduce the inspection workload and cost, and ensure that the product is always of high quality by adjusting the production process in time. The instrument can optimize the manufacturing parameters, shorten the idle time of the machine after replacing the inductive sensor, realize the fast manufacturing control function and good quality management.

Our equipment: The device utilizes the following principle: the hardened layer has almost no resistance to ultrasonic waves, while materials that have not undergone hardening treatment will scatter a large amount of ultrasonic waves. The detection system records the backscatter signal and processes it with our electronic measuring elements. Through comprehensive automatic data evaluation, the final hardened depth of the material can be obtained.

Features ● Measurement equipment can be integrated into the production process. ● The measurement accuracy is very high: the error in determining the surface depth value is about ± 0.1mm (metallographic method) ● Quickly obtain measurement results: each measurement only takes a few seconds. ● Large numbers of parts can be evaluated very quickly. ● By using different wedges, workpieces of different sizes can be measured. ● The device can move freely (total weight: 780g). ● Parameters can be easily adjusted according to customer requirements.

Technical parameters ●Ultrasonic pulse transducer ●Ultrasonic receiving frequency:1—20 MHz. ●Two receiving and sending channels. ●Signal envelope processing. ●Acoustic coupling is achieved through special wedges.

Standard configuration

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: fast charging flaw detector flaw detector ultrasonic lithium ion battery ultrasonic flaw detector |

|

Light Weight Small Volume Mini 1mm Ut Flaw Detector |

|

Portable 64 Ch Hpa-500 Phased Array Ultrasonic Flaw Detector Phased Array Flaw Detector |

|

Mini Portable Industrial Non Destructive Ut Flaw Detector |

|

Auto Calibration Digital 7" Portable Ultrasonic Flaw Detector |

|

Carbon Steel Ultrasonic Asme 19mm Calibration Test Block |

|

1/2-T-R High Resolution TFT Screen (640×480) Railway Digital Ultrasonic Flaw Detector |