Leeb Hardness Tester Metal Portable Hardness Testing Machine RHL170

with printer Advantages - Large screen(128×64 dot matrix LCD), showing all functions and

parameters.

- Test at any angle, even upside down.

- Support "forged steel (Steel)" material, when using the D/DC impact

device test "forged" sample, can read HB value directly, without

the need for manual checking table.

- Wide measuring range. It can measure the hardness of all metallic

materials. Direct display of hardness scales HRB, HRC, HRA, HV, HB,

HS, HL and three types of strength values immediately.

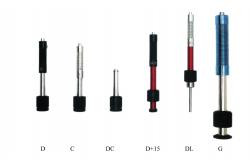

- Seven impact devices are available for special application.

Automatically identify the type of impact devices.

- Large capacity memory could store 600 groups (Relative to average

times32~1 ) information including single measured value, mean

value, testing data, impact direction, impact times, material and

hardness scale etc.

- Upper and lower limit can be preset. It will alarm automatically

when the result value exceeding the limit.

- Battery information indicates the rest capacity of the battery and

the charge status.

- User calibration function.

- USB port with the PC humanity multi-functions data proceeding

software.

- Original imported high speed thermal printer support the immediate

printing function. It can save data permanently.

- NI-MH rechargeable battery as the power source. Charge circuit

integrated inside the instrument. Continuous working period of no

less than 200 hours (EL off and no printing).

- Auto power off to save energy.

- Industrialized housing design, sturdy, compact, portable, high

reliability, suitable for harsh operating environment, vibration,

shock and electromagnetic interference.

- Excellent after-sale service system for high quality products---two

years’ guarantee and all life maintenance. Easy to buy and

comfortable to use.

Main Application - Die cavity of molds

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other

equipment

- Heavy work piece

- The installed machinery and permanently assembled parts

- Testing surface of a small hollow space

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for

large-scale work piece.

Technical SpecificationsMeasuring range:HLD (170-960),HRC (17.9-69.5),HB (19-683),HV

(80-1042),HS (30.6-102.6),HRA(59.1-88),HRB (13.5-101.7)- Measuring direction:360°

- Hardness Scale:HL,HB,HRB,HRC,HRA,HV,HS

- Display:dot matrix LCD,128×64 dots

- Data memory: 600 groups max.(relative to impact times 32~1)

- Printing paper: width is (57.5±0.5)mm, diameter is 30mm

- Battery pack: 6V NI-MH

- Battery charger: 9V/500mA.

- Continuous working period:about 200hours(With backlight off, no

printing)

- Communication interface:USB2.0

- Dimensions: 210 x 85 x 45mm (host).

- Weight: about 0.6kg (host).

Configuration| | No. | Item | Quantity | Remarks | | Standard Configuration | 1 | Main Unit RHL-170 | 1 | | | 2 | D type impact device | 1 | With cable | | 3 | Standard test block | 1 | | | 4 | Cleaning brush (I) | 1 | | | 5 | Small support ring | 1 | | | 6 | Battery Charger | 1 | 9V 500mA | | 7 | Paper for printing | 1 | | | 8 | Manual | 1 | | | 9 | Data Pro software | 1 | | | 10 | Communication cable | 1 | | | 11 | Instrument case | 1 | | | Optional Configuration | 12 | Cleaning brush (II) | 1 | For use with G type impact device | | 13 | Other type of impact devices and support rings | | |

Testing range:Other type of impact devices | Material | Method | Impact device | | D/DC | D+15 | C | G | E | DL | Steel and cast steel | HRC | 20~68.5 | 19.3~67.9 | 20.0~69.5 | | 22.4~70.7 | 20.6~68.2 | | HRB | 38.4~99.6 | | | 47.7~99.9 | | 37.0~99.9 | | HRA | 59.1~85.8 | | | | 61.7~88.0 | | | HB | 127~651 | 80~638 | 80~683 | 90~646 | 83~663 | 81~646 | | HV | 83~976 | 80~937 | 80~996 | | 84~1042 | 80~950 | | HS | 32.2~99.5 | 33.3~99.3 | 31.8~102.1 | | 35.8~102.6 | 30.6~96.8 | Cold work tool steel | HRC | 20.4~67.1 | 19.8~68.2 | 20.7~68.2 | | 22.6~70.2 | | | HV | 80~898 | 80~935 | 100~941 | | 82~1009 | | Stainless steel | HRB | 46.5~101.7 | | | | | | | HB | 85~655 | | | | | | | HV | 85~802 | | | | | | Grey cast iron | HRC | | | | | | | | HB | 93~334 | | | 92~326 | | | | HV | | | | | | | | Nodular cast iron | HRC | | | | | | | | HB | 131~387 | | | 127~364 | | | | HV | | | | | | | | Cast aluminium alloys | HB | 19~164 | | 23~210 | 32~168 | | | | HRB | 23.8~84.6 | | 22.7~85.0 | 23.8~85.5 | | | BRASS(copper-zinc alloys) | HB | 40~173 | | | | | | | HRB | 13.5~95.3 | | | | | | | BRONZE(copper-aluminium/tin alloys) | HB | 60~290 | | | | | | | Wrought copper alloys | HB | 45~315 | | | | | |

| Available type of impact device | DC | D+15 | C | G | E | DL | | Test hole or hollow cylindrical | Test groove or reentrant surface | Test small, light, thin parts and surface of hardened layer | Test large, thick, heavy and rough surface steel | Test super high hardness material | Test slender narrow groove or hole |

Testing conditions:| Type of impact device | DC(D)/DL | D+15 | C | G | E | Impacting energy Mass of impact body | 11mJ 5.5g/7.2g | 11mJ 7.8g | 2.7mJ 3.0g | 90mJ 20.0g | 11mJ 5.5g | Test tip hardness: Dia. Test tip: Material of test tip: | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 3mm Tungsten carbide | 1600HV 5mm Tungsten carbide | 5000HV 3mm synthetic diamond | Impact device diameter: Impact device length: Impact device weight: | 20mm 86(147)/ 75mm 50g | 20mm 162mm 80g | 20mm 141mm 75g | 30mm 254mm 250g | 20mm 155mm 80g | | Max. hardness of sample | 940HV | 940HV | 1000HV | 650HB | 1200HV | | Mean roughness value of sample surface Ra: | 1.6μm | 1.6μm | 0.4μm | 6.3μm | 1.6μm |

Min. weight of sample: Measure directly Need support firmly Need coupling tightly | >5kg 2~5kg 0.05~2kg | >5kg 2~5kg 0.05~2kg | >1.5kg 0.5~1.5kg 0.02~0.5kg | >15kg 5~15kg 0.5~5kg | >5kg 2~5kg 0.05~2kg | Min. thickness of sample Coupling tightly Min. layer thickness for surface hardening | 5mm ≥0.8mm | 5mm ≥0.8mm | 1mm ≥0.2mm | 10mm ≥1.2mm | 5mm ≥0.8mm |

| Size of tip indentation | | Hardness 300HV | Indentation diameter Depth of indentation | 0.54mm 24μm | 0.54mm 24μm | 0.38mm 12μm | 1.03mm 53μm | 0.54mm 24μm | | Hardness 600HV | Indentation diameter Depth of indentation | 0.54mm 17μm | 0.54mm 17μm | 0.32mm 8μm | 0.90mm 41μm | 0.54mm 17μm | | Hardness 800HV | Indentation diameter Depth of indentation | 0.35mm 10μm | 0.35mm 10μm | 0.35mm 7μm | -- -- | 0.35mm 10μm |

Support rings for Shaped Materials:Other type of support rings

|