Aluminum Penetrant Calibration Block Non Destructive Testing With Heat Treatment

|

|

penetrant calibration block test block PT test specimen developer,remover

Model:YM-B All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B Depth:100µm Width target value:0.5µm Test standard:ISO 3452-3:1998(E),JB/T6064

Model:YM-C All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B Depth:100µm Width target value:0.5µm Test standard:ISO 3452-3:1998(E),JB/T6064

Model:YM-D All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B Depth:150µm Width target value:0.5µm,1.0μ and 1.5μ Test standard:ISO 3452-3:1998(E),JB/T6064

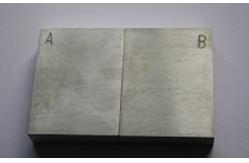

Model: YM-A Aluminum Comparator Block Through the physical and chemical test type A block material for LY12 aluminum alloy for materials, the chemical components conform to the provisions of ASTM,GB/T3190 By means of a micrometer measurement block length is 76 + 0.1 ㎜, and the width fifty + / - 0.1 ㎜, thick and ± 1 ㎜. Cut along the length center evenly divided into two pieces, and in block A and B and unity Numbers, block length orientation and plate rolling direction. Milling, grinding the surface roughness after treatment for Ra = 1.2 u m - 2.5 u m. Color: Visual its color is silvery white. Oxidizing property :In -55 ℃ ~ 200 ℃ - store between three years not metamorphism, no oxidation, Crack: In the same Numbers of the A and B block with dye penetrant inspection method measured random crack 3 μ m, 3 μ m ~ 5 μ m and more than 5 μ m open crack on one side not less than four, and there are two above width is not more than 3 μ m open crack. Block A and B on the surface crack distribution is similar. ASTME165 standard

Type I Penetrate block

Type II Penetrate block

Penetrate Block B3

Penetrate Block B5

Penetrate block PSM-5

|

| Product Tags: ndt testing equipment non destructive testing machine |

|

20/85/60 Degree Gloss Meter Triangle ISO 2813 ASTM-D2457 DIN 67530 |

|

Touch Screen Portable Surface Roughness Tester SRT5050 Non Destructive Testing Equipment |

|

Handheld Digital Touch Screen Xrf Alloy Analyzer |

|

High Voltage Pinhole Detector Portable Holiday Detector Nondestructive Flaw Detection |

|

High Radiation 250kv XXQ-2505 Portable X Ray Flaw Detector |

|

Metal Mirror Surface And Coating Surface Gloss Meter HGM-B60MS |