Bluetooth PLL Technique Coating Thickness Gauge Painting Thickness

Meter Temperature compensation:the unique technology PLL【phase

locked loop】

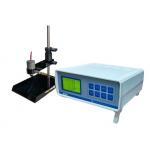

TG-6000 SERIES Coating Thickness Gauges use latest technology;it

can configure multi different probe to measure different work

pieces;2.4 inches TFT color screen;Bluetooth 2.0 wireless

communication technique; We develop our own PLL technique to make

measuring work more stable;inverted display,display in Chinese and

English,multi measuring mode and so on, These features can make

gauge more suited to the job requirements of the industrial field

and provide customers with more convenience. Its performance has

reached the contemporary international advanced level of similar

gauge. Principles of measurementTG-6000 SERIES Coating Thickness Gauges can choose different kind

of probes. For example, Fe probe use magnetic induction method to

measure the thickness of non-magnetic coating on ferromagnetic

material, NFe probe use eddy current method to measure the

thickness of non-conductive coating on conductive metal. Applied rangeThis gauge can be used widely in machinery,

automobile,shipbuilding,petroleum,chemical,electroplating, spraying

plastics, enamel, plastics and so on.

Function- Display :2.4inches color screen can be adjusted to your preferred

brightness, then our measuring work will be more easier.

- Probe:depend on which type of gauge.

- Data interface: bluetooth 2.0 wireless.

- Temperature compensation:the unique technology PLL【phase locked

loop】.

- Measuring mode:simplify,monitoring,statistical,minimum value

capture.

- Calibration:matrix,system,One-point.

- Permanent calendar:time, or save the data information with

measuring data if operator doing measuring work.

- Saving method: Manual or automatic.

- Measuring speed:single or continuous measurement.

- Language: English.

- Gauge information: can check gauge software version and

manufacturer information.

- Restore factory settings.

Technique parameter| Gauge parameter | | Probe type | F | N | | Theory | Magnetic induction | Eddy current | | Temperature compensation | PLL technique | | Measure range | Depend on Probe | | Display | 2.4 inch TFT color screen,320*240 resolution | | Data interface | Bluetooth 2.0, can be communicated with PC and printer by wireless | | Saving | Auto and Manual save, 1000 saving files, each file can save 12 data | | Calibration | Matrix, system, One-point | | Measuring speed | Single, continuous | | Language | English | | Calender | Information of date and measure data of date | | Unit | Metric or British system | | Back light | Manual set 6 different levels of brightness | | Shutdown | Manual or auto shutdown | | Measure mode | Simplify; Minimum value capture; Monitoring mode; Statistical |

| Gauge parameter | | Working environment | Humidity:≤90%;

Temperature:-10℃~+40℃ | | Working period | Over 10,000 data(lowest back-light level) | | Power | 2 AA batteries | | Size | 150mm(L)*68mm(W)*33mm(H) | | Weight | 220g(include batteries) |

| Probe parameter | | Type | F0.5 | F1.2 | N1.2 | F3 | F5 | F10 | | Measure range | 0~0.5 | 0~1.25 | 0~1.25 | 0~3 | 0~5 | 0~10 | | Min plane diameter for matrix | 10 | 15 | 19 | 16 | 18 | 22 | | Min radius of matrix(concave) | 5 | 6 | 10 | 10 | 10 | 12 | | Min radius of matrix(convex) | 1.5 | 1.5 | 5 | 5 | 5 | 5 |

| Probe parameter | | Type | F0.5 | F1.2 | N1.2 | F3 | F5 | F10 | | Min diameter for Internal corrosion protection probe | 40 | 42 | 80 | 60 | 60 | 70 | Deviation

(H is thickness) | ±(1~3)%H±1μm,

Or H±2μm | ±(2~3)%H

±2μm | ±(2~4)%H

±2μm | | Probe type | F for magnetic,N for eddy current | | Min thickness for matrix | F:1mm, N:0.5mm | | Attention:the units above is MM. |

|