HCDX-10000 Magnetic Particle Testing Equipment Magnetic Particle inspection Equipment

|

|

Model HCDX-10000 Magnetic Particle inspection Equipment

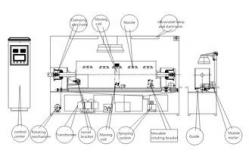

1. Equipment composition Control center (including operation panel, control panel and main power board etc.) Control system (SIEMENS) Main engine (including clamping mechanism, magnetization mechanism, electrode mechanism, etc.) Magnetic suspension spray system Darkroom system Coil movement device Clamping and rotating mechanism Bracket rotating mechanism

2. Inspection workpiece:

Shaft specification: Workpiece rotation diameter of less than 400mm, within a length of 2000mm

3. Equipment capacity: Running time: more than 500 hours / month

4. Local design standards:

JB/T8290 - 1998 "magnetic particle flaw detector"

5. Main technical indexes Circumferential magnetization current AC:0 - 10000A FWDC, continuous adjustable, with power off phase control Longitudinal magnetization magnetic potential AC:0 - 16000AT, continuous adjustable, with power off phase control. Electrode spacing: 200 - 2500mm. Magnetization method: direct pass method, coil method. Magnetization mode: three kinds of circumferential magnetization, longitudinal magnetization and compound magnetization can be flexibly chosen. The use of the environment: - 10 C and C +40, relative humidity is less than 90%. Storage environment: temperature of - 20 C and 60 C, relative humidity is less than 70%. Non corrosive Gas dust and high frequency electromagnetic pollution. Sensitivity test: according to the People's Republic of China machinery industry standard JB/T6065 - 92, "magnetic powder testing standard test film", AII, test piece display clear. And standard DIN EN ISO 9934. Power supply: three-phase four wire, 380V + 10%, 50HZ, about 600A. Inspection surface: all surface cracks and other defects. Demagnetization AC: automatic attenuation type demagnetization. Demagnetization; DC:; ultra low frequency demagnetization Remanence: the maximum remanent magnetization after demagnetization is less than 0.3mT Workpiece rotation speed: 4-6rpm. (large workpiece bracket rotating, small workpiece clamping rotation) Magnetization coil: inner diameter 400mm. The coil moves in an electric way. Pneumatic clamping: clamping stroke 0-75mm. Air pressure: 0.4 - 0.8MP. Power control cabinet: 900 (width) * 1200 (long) * 2000 (high) mm. Test bed (including UV lamp): 1000 (width) * 3500 (long) * 2100 (high) mm. Temporary loading rate: less than 20%

6. Running program: manual and automatic

The automatic program is: clamping - liquid - magnetization - rotation observation (clamping and bracket rotation two) - demagnetization - loose clamp, the whole process is controlled by small industrial PLC (long workpiece, subsection magnetization)

7. Control center

The control center is based on programmable logic controller (PLC). Control cabinet as the main body, contains a variety of actuators, magnetization trigger circuit, the main transformer 8. Host The host is composed of main body, stainless steel tank, longitudinal magnetization, coil to weeks of moving mechanism, carrier rotating mechanism, sprinkler system, rail, pneumatic mechanism and circumferential and longitudinal main transformer Figure 2, each part of the equipment Body: horizontal sheet metal structure, making use of the high quality material of the equipment. Stainless steel collection tank: made of 1.5mm stainless steel. Longitudinal magnetizer: consisting of coils. The circumferential magnetizer consists of two electrically connected electrode plates and an electrode shaft. Suspension system of magnetic suspension: the injection quantity can be adjusted by moving the valve. With stirring device antimagnetic precipitation powder. The circuit is provided with a filter convenient for replacing. Rail: for supporting and moving coil and mobile electrode. Electrode box: welded by 10mm steel plate. Rotating mechanism: by the speed reduction motor through the chain transmission mechanism, the transmission roller to drive the workpiece Rotate or clamp workpiece rotation. Coil movement mechanism: consisting of a gear rack mechanism. The pneumatic mechanism consists of a cylinder, solenoid valve, control valve, air source treatment components, used for clamping, has Xiangtong electromagnetic, ensure the detection sensitivity. 9.Lighting Equipped with white light and UV light system. The intensity of UV irradiation is up to standard 10.Others An operating panel for mobile operation is installed on the host computer. The device is installed on the ground without the equipment foundation. Grease is butter. Install the muffler on the solenoid valve. Install air handling triple parts. Use a limit switch with excellent heat and dust resistance. The wires are wired at both ends 11.Features and functions Compound magnetization solves the problem that once the workpiece is magnetized in all directions without missing. The main circuit is contactless control, and the equipment is stable. The flaw detector adopts PLC centralized control. This machine adopts low voltage high current output current, ampere, adjustable. The working principle of overview: This machine with programmable logic controller (PLC) as the core, according to the detection process, send information by the sensor, after PLC treatment, were judged to control mechanical action related, according to set parameters, week longitudinal magnetization, using special thyristor phase-shift trigger integrated circuit to control the circumferential and longitudinal silicon controlled trigger circuit. Output trigger pulse Characteristic: Through touch screen input, storage, detection process, rapid call detection process. Part counter. Over current and under current sound and light alarm. Clamping function for both hands safety control. Magnetizing current and phase difference of 120 Eve joy. The electrode has a copper pad against sparking. 12.Business conditions 1. User owned (1) power supply: supply a designated place (a place), 380V, 50HZ, > 250A. (2) air source: supply a designated place (one) greater than 0.4Mpa. 2. delivery date (1) 60 working days after ordering, to the design, manufacture and inspection of the factory.

13. Selection of magnetizing current The circumferential magnetization current can generally be calculated in the lower order Continuous method: I=8D to 15D Residual magnetism method: I=20D ~ 40D I was in the current value of A D - specimen diameter or maximum width (mm) The above values are the reference values, and the actual work values shall be determined by the sensitivity test. 14. Magnetic suspension configuration: Preparation of magnetic suspension of water agent: Fluorescent magnetic powder: 2-3 g / liter Dispersant: 0.2%, check the weight of the liquid Rust inhibitor: 0.5%, check the weight of liquid Defoaming agent: 0.5 - 1 grams / liter Preparation of magnetic suspension for oil (use odorless kerosene = 96 DEG C, flash point) Fluorescent magnetic powder: 2-3 g / L, odorless kerosene Dispersant: 0.2%, check the weight of the liquid |

| Product Tags: magnetic particle inspection equipment mpi testing machine |

|

DC AC Tasla Meter Digital Gauss Meter For Inspecting Checking Flux Density |

|

High Sensitivity Gauss Tesla Meter Measure Dc Or Ac Magnetic Field And Flux Density |

|

UV-A 365&420 Single Channel uv irradiance meter Ultraviolet Radiometer |

|

Accuracy Uv Radiometer Measurement Of Light Sources And Irradiation Systems |

|

AC200v Coil Flaw Magnetic Crack Detector Magnaflux |

|

Magnetic Particle Flaw Detector Accessories Dead Weight Test Block With Hole |